hy..

finally I get all parts,time and wish to convert my 3B hall sensor to ABY.

all parts that you need for conversation :

AAN/ABY/ADU oil pump (pipe from oil pump in oil pan must stay 3B,AAN is different)

AAN timing belt

AAN water pump

AAN timing belt tensioner

AAN cam pulley

AAN inner and external timing belt cover ,

AAN metal cover witch had timing mark

AAN water pipe for turbo cooling

AAN HALL SENSOR

of course you also must have one AAN engine block and head to copy wholes for tensioner and hall sensor.

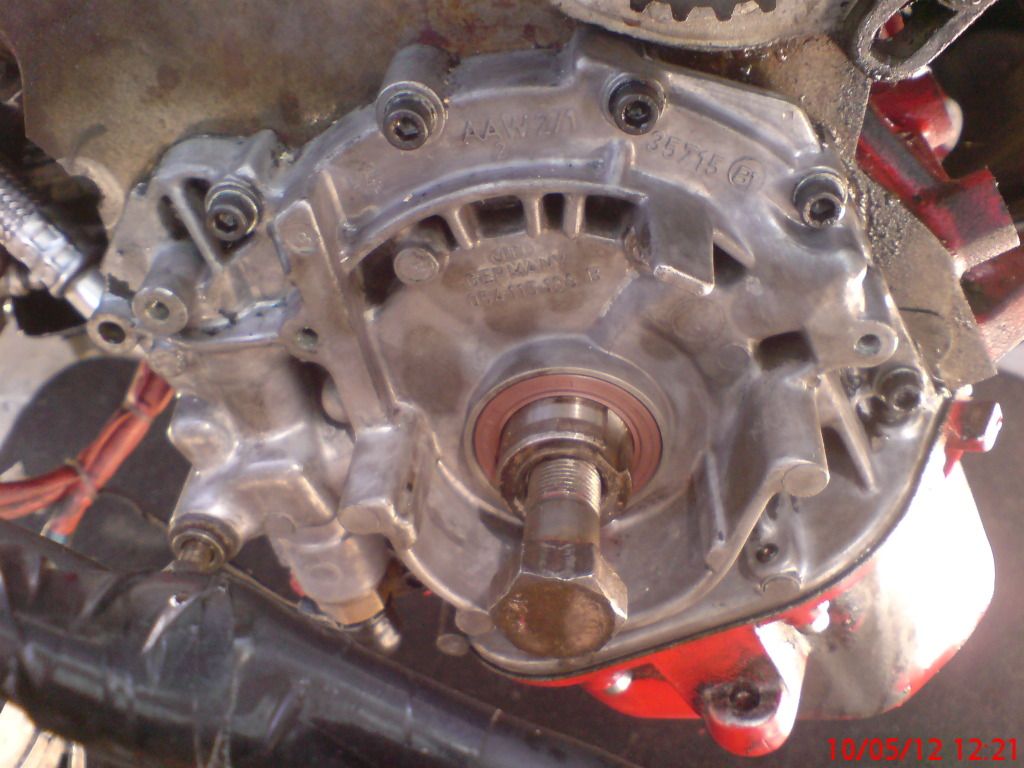

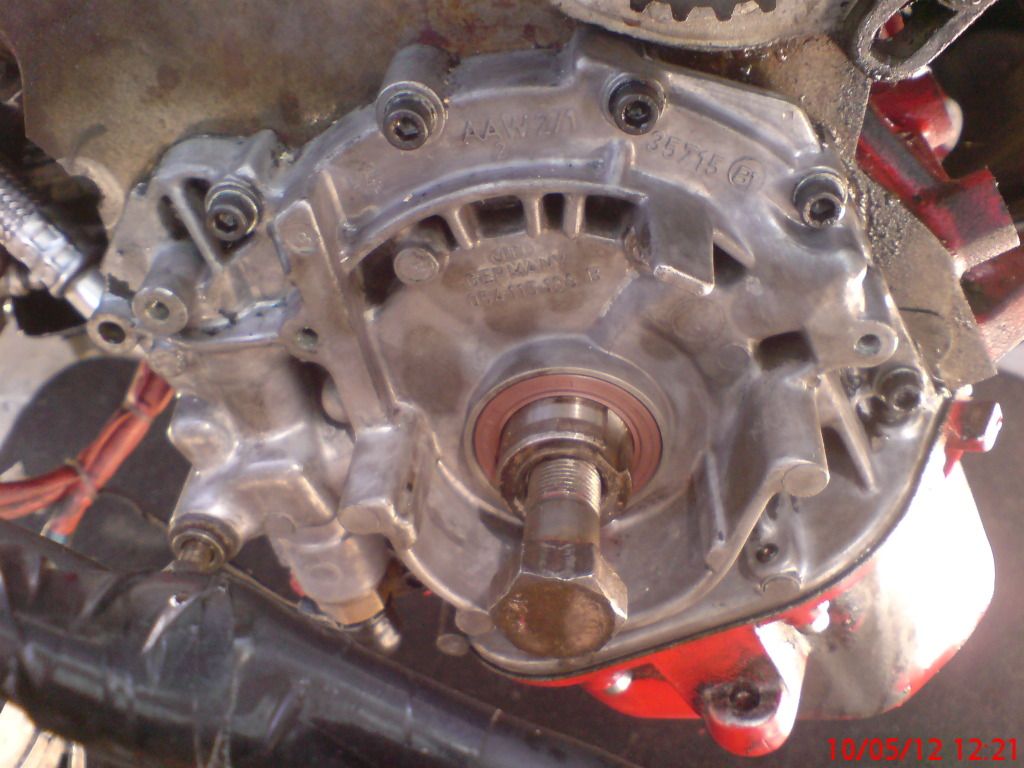

here was the start, oil pump changed.

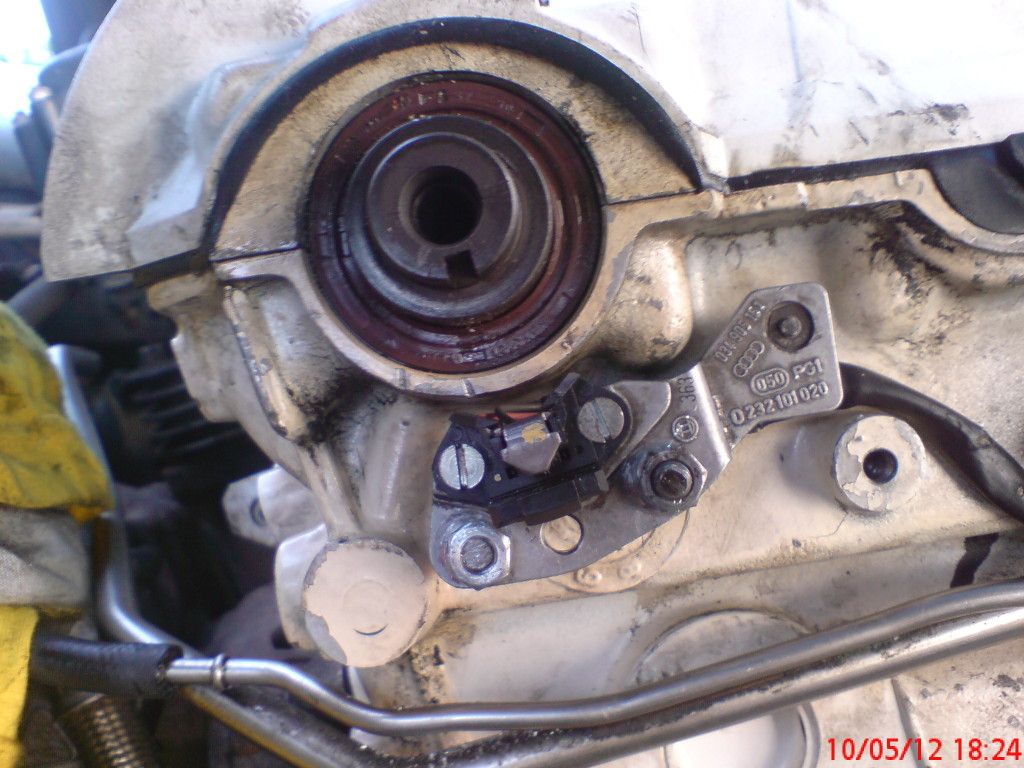

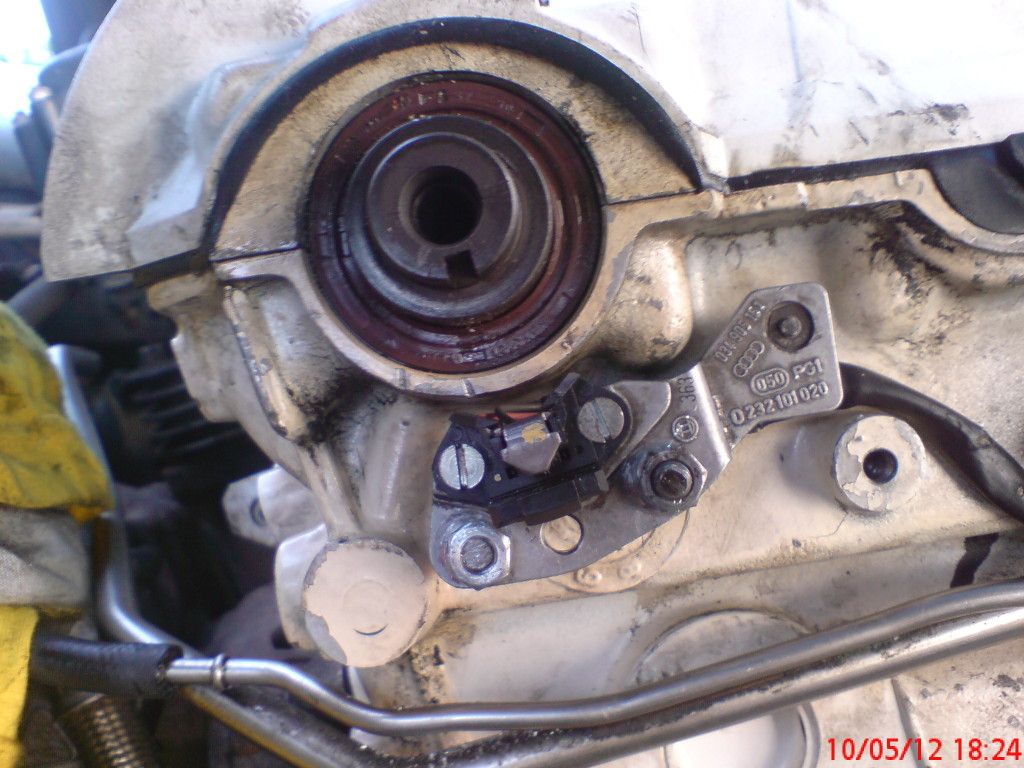

here is 3B head without hall sensor

than you must produce this custom tool to get mark for wholes on head

drill this 2 wholes for 8mm with 5mm bore , because after that you must put 6mm bolt on it.

don't worry with right whole you will pass truth head to cam chain, after that you must clean that inside head . left whole is ok.

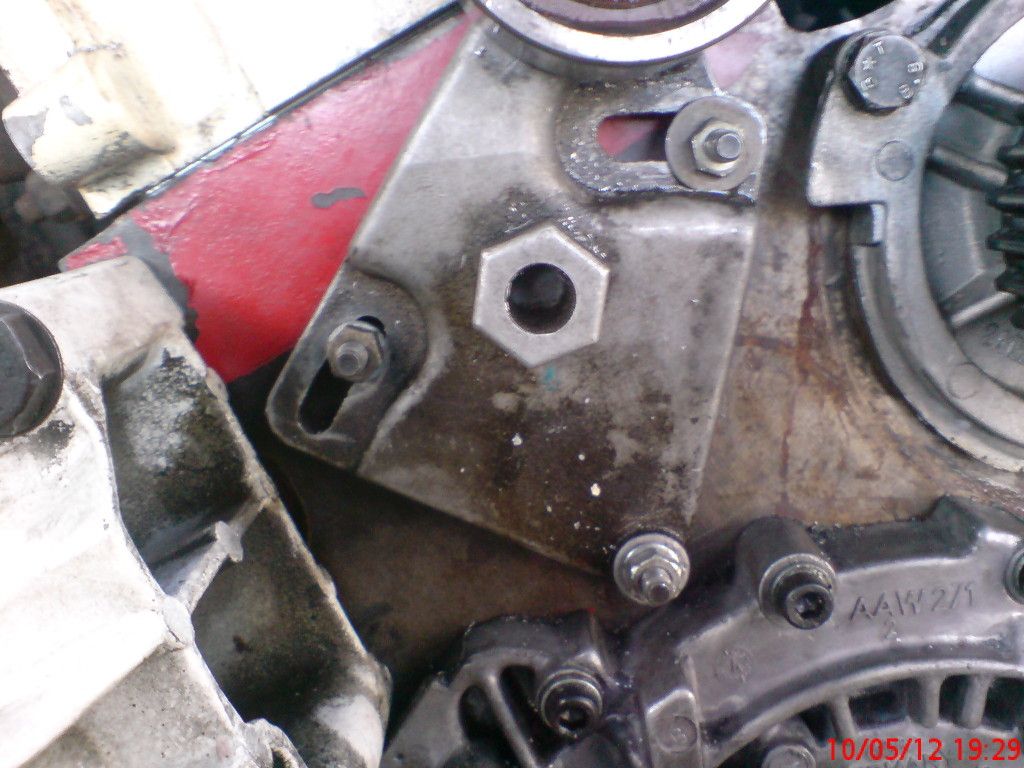

after that drill the same size bore (5mm) into the engine block to make wholes for timming belt tensioner.

at that place you will get into the water of engine block, don't worry, this is normal. because AAN block is stronger inside at that place. before this 3 wholes relese engine water out. don't drill it further . when you see the water. than is ok.

use this 6mm bolts (without head) on engine block and head . messure it how long they have to be.

DON'T FORGET to use liquid metal glue (2 component) to hold that bolts on place , and also they will sealed wholes from water and oil.

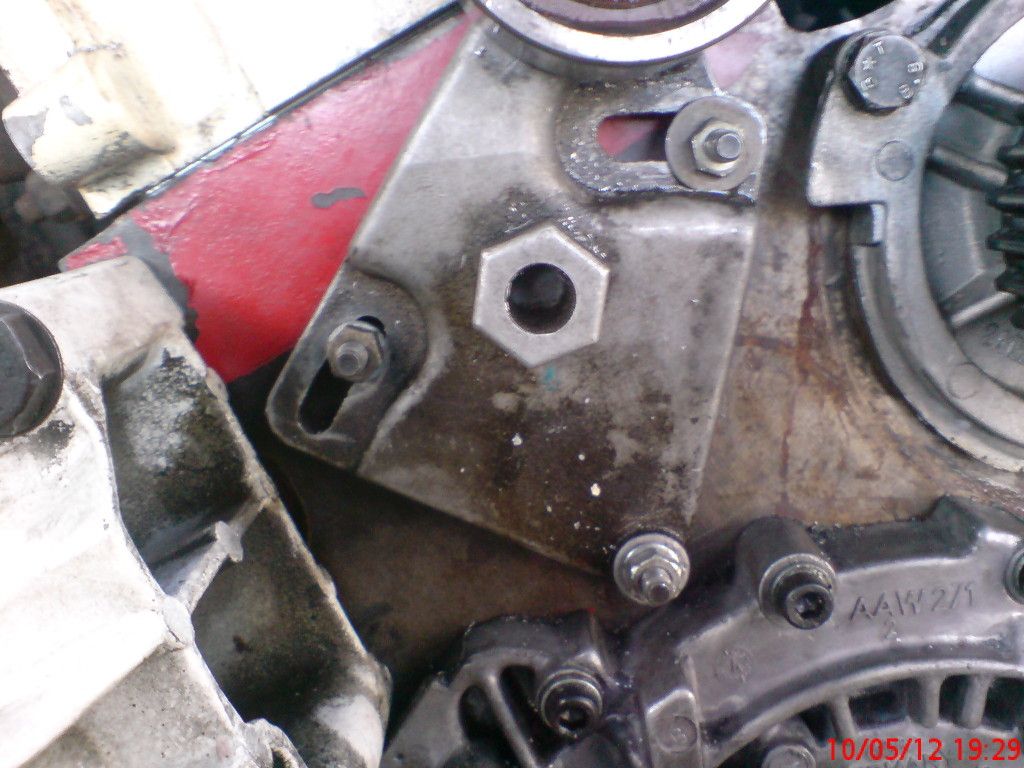

hall sensor and tensioner is at place !

use this 4 ,6mm nut , because with them your hall sensor will be 1cm further , and this is exactly the right place for it.

tensioner is at place too !

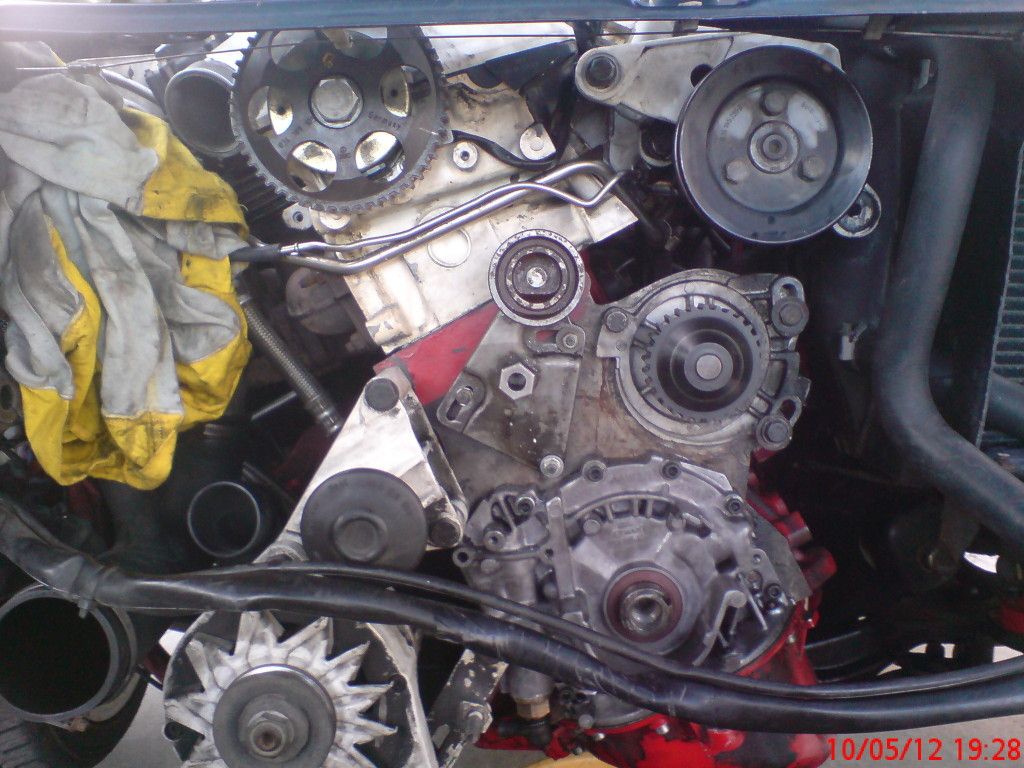

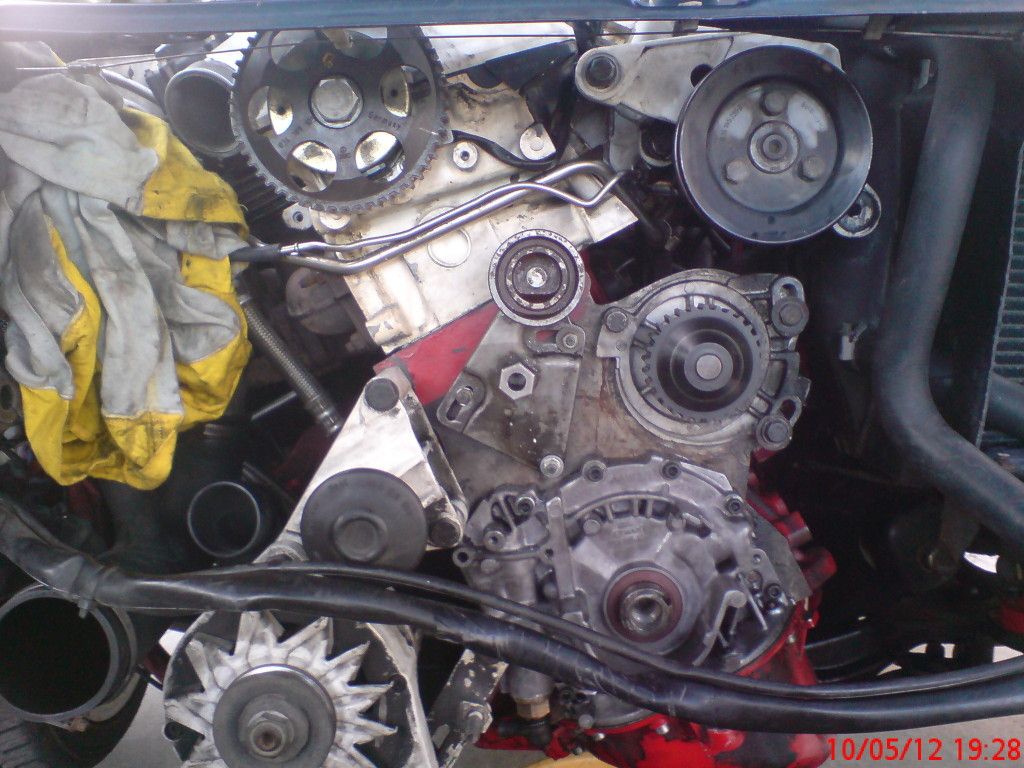

change the watter pump, put engine on his marks , and it is done !

my engine is finally at good position, 100% at good marks and no more problem with hall sensor in distributor. it runs better , smoother and idle is perfect !

be patience.. and everithing will be ok !

if somebody will need this custom tool for hall sensor marks it is here, and for block too!

if you have any questions.. I'm here.

Best Regards

Igor

finally I get all parts,time and wish to convert my 3B hall sensor to ABY.

all parts that you need for conversation :

AAN/ABY/ADU oil pump (pipe from oil pump in oil pan must stay 3B,AAN is different)

AAN timing belt

AAN water pump

AAN timing belt tensioner

AAN cam pulley

AAN inner and external timing belt cover ,

AAN metal cover witch had timing mark

AAN water pipe for turbo cooling

AAN HALL SENSOR

of course you also must have one AAN engine block and head to copy wholes for tensioner and hall sensor.

here was the start, oil pump changed.

here is 3B head without hall sensor

than you must produce this custom tool to get mark for wholes on head

drill this 2 wholes for 8mm with 5mm bore , because after that you must put 6mm bolt on it.

don't worry with right whole you will pass truth head to cam chain, after that you must clean that inside head . left whole is ok.

after that drill the same size bore (5mm) into the engine block to make wholes for timming belt tensioner.

at that place you will get into the water of engine block, don't worry, this is normal. because AAN block is stronger inside at that place. before this 3 wholes relese engine water out. don't drill it further . when you see the water. than is ok.

use this 6mm bolts (without head) on engine block and head . messure it how long they have to be.

DON'T FORGET to use liquid metal glue (2 component) to hold that bolts on place , and also they will sealed wholes from water and oil.

hall sensor and tensioner is at place !

use this 4 ,6mm nut , because with them your hall sensor will be 1cm further , and this is exactly the right place for it.

tensioner is at place too !

change the watter pump, put engine on his marks , and it is done !

my engine is finally at good position, 100% at good marks and no more problem with hall sensor in distributor. it runs better , smoother and idle is perfect !

be patience.. and everithing will be ok !

if somebody will need this custom tool for hall sensor marks it is here, and for block too!

if you have any questions.. I'm here.

Best Regards

Igor

).

).

Comment