It's been a busy old weekend. We started getting ready on Friday night at which point the car looked like this.

And this afternoon, it now looks like this.

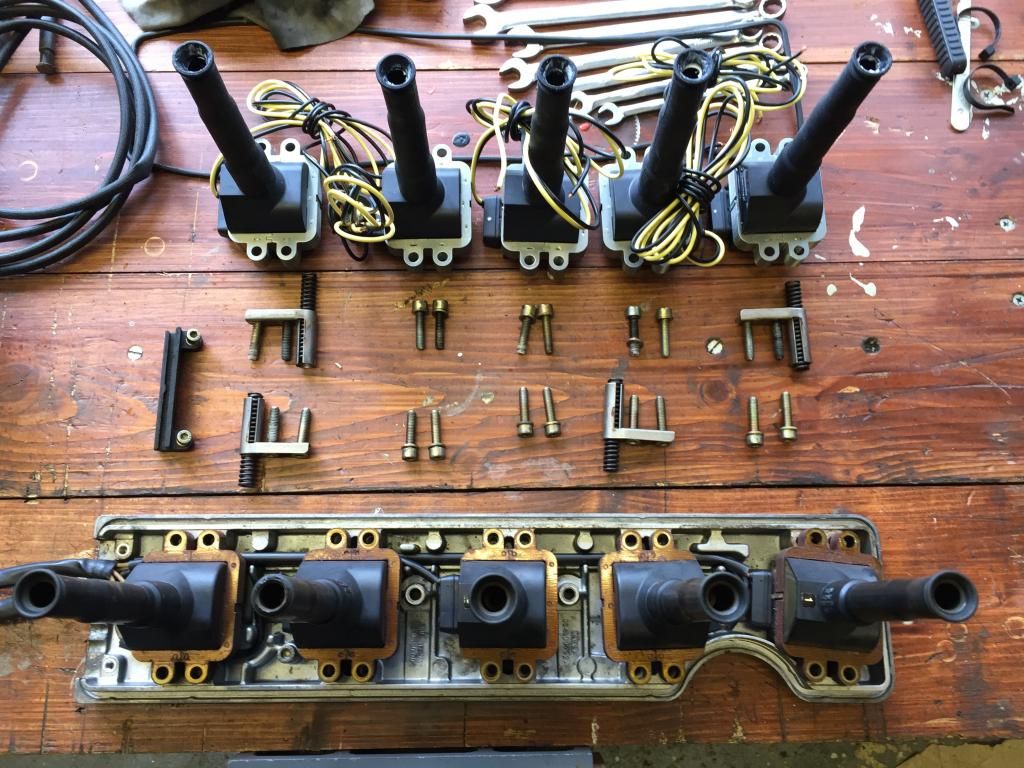

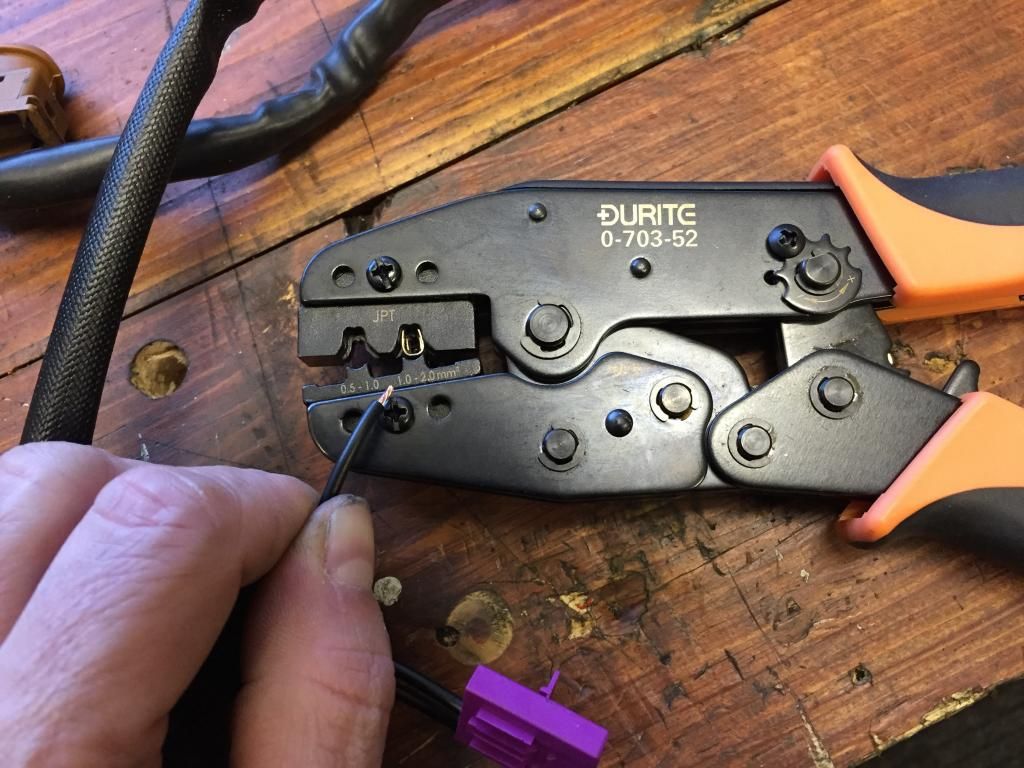

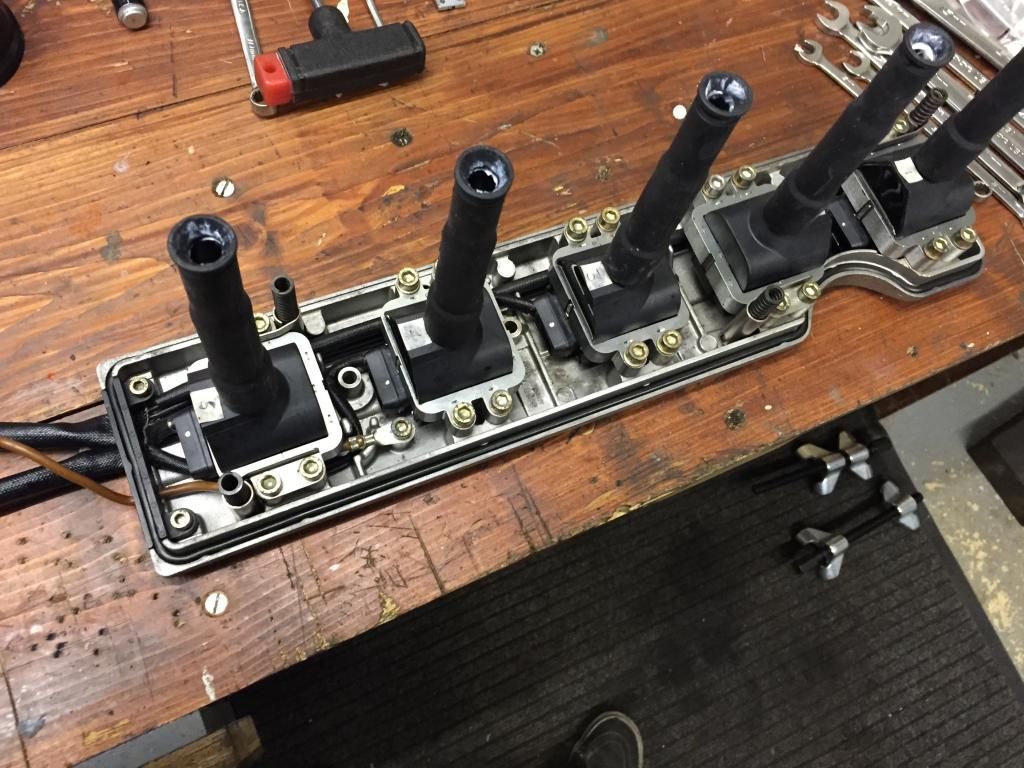

I have to say it has been one of the most enjoyable cars I've ever stripped. Not a single seized or sheared bolt. The plating on all of the threads was still nice, even if the head looked a little grotty. A big thanks to Acidburn and the other guys who chipped on on my running gear teardown thread, the advice was spot on

Undoing things has demonstrated why it's never driven that well. All of the bushes were well past tired and for example as we stripped the front wishbones the bushes came off in pieces.

I'm looking forward to getting it back together to see the difference. I'm on a bit of a tight schedule as it's booked in to go to Centre Of Gravity a week on Thursday for it's alignment and corner weighting, it's a 6 week waiting list, so I can't miss my deadline. I'm having all of the bushes pressed out tomorrow and I'm then off to the powder coaters probably Wednesday or Thursday to get ready for re-assembly.

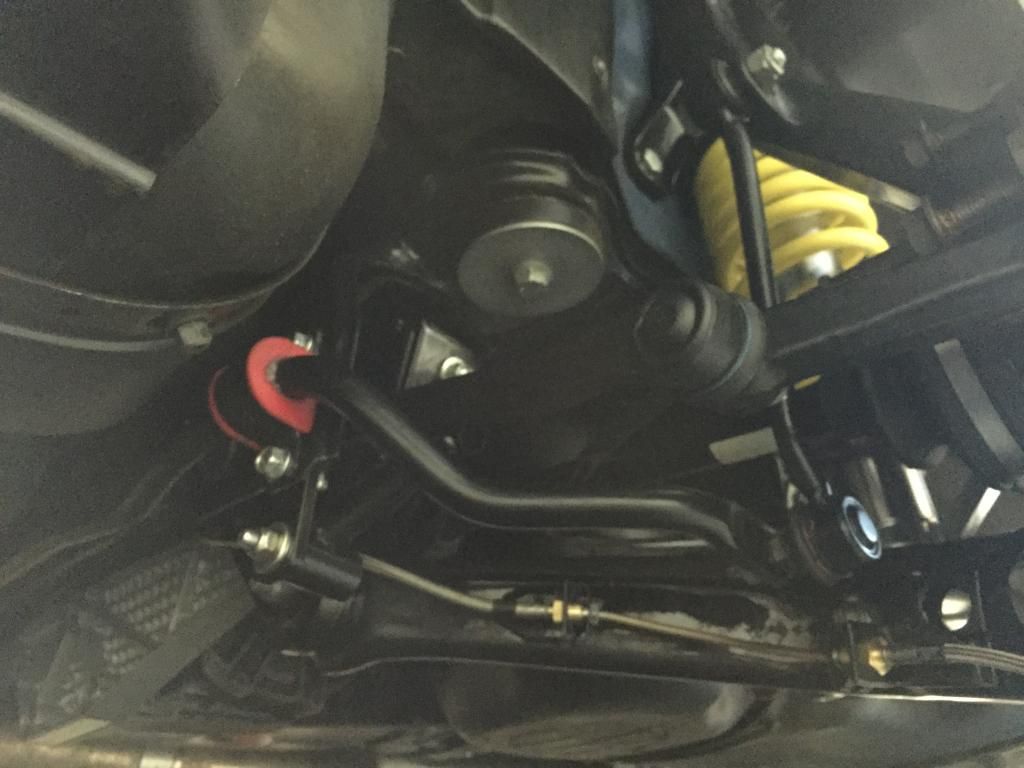

To answer a few questions. The tie rod adjusters are the bigger Bainbridge ones he makes, as are his alloy subframe bushes and rear toe link bushes. The front wishbone bushes are those special material ones which Mance made (work of art!) and I'm using Mance mount saver 2's in stock top mounts. The balance of the bushes are Powerflex Black, it's a Neuspeed rear ARB and KW variant 3's. I've bought Apikol blue rear diff mount and bushes, but they're not here yet. Everything else is new factory parts (from TPS and Audi Tradition), engine mounts, gearbox mounts etc. It's the factory 322mm big brake set and matching rear discs and new callipers all round, Pagid RS-42 blue brake pads. Just for reference in case anyone else has the same trouble, yes the front callipers are 993 Turbo, but the rear callipers are 964 Turbo. You'll get a nasty fright asking Dr Porsche's little helpers for the price of callipers these days, they've almost trebled in price in two years, to keep up with the price of a 993 turbo!

Ross, I saw the mod on the rear shock towers, it's a pain that the adjuster is shrouded up there. I'm guessing I've got to cut that slot. Also, front wings and tailgate are both reasonably priced. I'd guess if you bought used, you'll encounter the same problems.

I'll keep the pictures coming

And this afternoon, it now looks like this.

I have to say it has been one of the most enjoyable cars I've ever stripped. Not a single seized or sheared bolt. The plating on all of the threads was still nice, even if the head looked a little grotty. A big thanks to Acidburn and the other guys who chipped on on my running gear teardown thread, the advice was spot on

Undoing things has demonstrated why it's never driven that well. All of the bushes were well past tired and for example as we stripped the front wishbones the bushes came off in pieces.

I'm looking forward to getting it back together to see the difference. I'm on a bit of a tight schedule as it's booked in to go to Centre Of Gravity a week on Thursday for it's alignment and corner weighting, it's a 6 week waiting list, so I can't miss my deadline. I'm having all of the bushes pressed out tomorrow and I'm then off to the powder coaters probably Wednesday or Thursday to get ready for re-assembly.

To answer a few questions. The tie rod adjusters are the bigger Bainbridge ones he makes, as are his alloy subframe bushes and rear toe link bushes. The front wishbone bushes are those special material ones which Mance made (work of art!) and I'm using Mance mount saver 2's in stock top mounts. The balance of the bushes are Powerflex Black, it's a Neuspeed rear ARB and KW variant 3's. I've bought Apikol blue rear diff mount and bushes, but they're not here yet. Everything else is new factory parts (from TPS and Audi Tradition), engine mounts, gearbox mounts etc. It's the factory 322mm big brake set and matching rear discs and new callipers all round, Pagid RS-42 blue brake pads. Just for reference in case anyone else has the same trouble, yes the front callipers are 993 Turbo, but the rear callipers are 964 Turbo. You'll get a nasty fright asking Dr Porsche's little helpers for the price of callipers these days, they've almost trebled in price in two years, to keep up with the price of a 993 turbo!

Ross, I saw the mod on the rear shock towers, it's a pain that the adjuster is shrouded up there. I'm guessing I've got to cut that slot. Also, front wings and tailgate are both reasonably priced. I'd guess if you bought used, you'll encounter the same problems.

I'll keep the pictures coming

so it's kind of finished now I guess. I'm not going to tune it or change anything further, it's at the top of its game. Once the nicer weather's here I'll get some nice photos, I'm going to try and get to a couple of the meets this year too

so it's kind of finished now I guess. I'm not going to tune it or change anything further, it's at the top of its game. Once the nicer weather's here I'll get some nice photos, I'm going to try and get to a couple of the meets this year too

Comment