Announcement

Collapse

No announcement yet.

Project '96 Refurb

Collapse

X

-

Believe me when you try that you will see there isn't much pressure on screwdriver Its fast cheep and reliable

Its fast cheep and reliable

Leave a comment:

-

Originally posted by mario2005 View PostNext time to undo crankshaft bolt just use big screwdriver and put it in hole between engine and gearbox and stick it into round thing what looks like gear i don't know how it on English

i don't know how it on English

whatever you now and that's it it will hold and you can undo the big crankshaft bolt

whatever you now and that's it it will hold and you can undo the big crankshaft bolt

That would be the flywheel! There are locking tools around that use the fly wheel to lock the crank, but i would think locking it with a screwdriver could possibly remove a tooth from the flywheel. That bolt is done up to 200nm + 180degrees and takes some un-doing!

The 2x2 box section doesnt damage anything and is very easy!

Leave a comment:

-

welding the subframes and wishbones will be free so i'll get them done.

turrets not so easy as i dont have a welder in the garage. Maybe one day when the car is on the road!

Leave a comment:

-

Next time to undo crankshaft bolt just use big screwdriver and put it in hole between engine and gearbox and stick it into round thing what looks like gear i don't know how it on English

i don't know how it on English

whatever you now

whatever you now and that's it it will hold and you can undo the big crankshaft bolt

and that's it it will hold and you can undo the big crankshaft bolt  Only problem you need somebody to help you to hold screwdriver

Only problem you need somebody to help you to hold screwdriver

Leave a comment:

-

If you are doing the welding yourself and are already cleaning/painting them then I would have thought it was worth it a minimal extra work/cost.Originally posted by willg54 View PostI suppose it could be worth it, but i think you'd notice the wishbones a lot more than the subframe.

If you can I would deffo recommend the rear strut brace, the towers can move quite a bit.Originally posted by willg54 View PostI'd looked into that strut brace, looks a good mod!! I've got the whiteline RARB to go on so hopefully that'll help but if i still feel the need, the strut brace will happen!

Leave a comment:

-

Rear strut brace is a really good mod.

Rear strut brace is a really good mod.

Seam welding the subframes also seals the two pressed halves together should help them last longer

If the ball pops out easy its probably pretty knackered.

IIRC the later 6spd ball joints are a slightly larger diameter so you have to trim them down a tad to fit in the S2 linkage arm

Leave a comment:

-

Originally posted by andy10v View PostIs it worth seam welding the subframes if you are doing the wishbones?

Rear strut brace is good when you have the welder out.

I suppose it could be worth it, but i think you'd notice the wishbones a lot more than the subframe.

I'd looked into that strut brace, looks a good mod!! I've got the whiteline RARB to go on so hopefully that'll help but if i still feel the need, the strut brace will happen!

Leave a comment:

-

Is it worth seam welding the subframes if you are doing the wishbones?

Rear strut brace is good when you have the welder out.

Leave a comment:

-

dp would be a DIY job

brake lines are on the list...missed that one off!

Is that joint actually broken?? i didnt get to look at it properly before it came out. But im guessing it should be able to just pull out....

What needs to be trimmed down on the 01E ball joint? And i like the sound of anti-air craft gun reload gear shift...reminds me of the TVR...loved the utterly mechanical clunkiness of it!

Leave a comment:

-

nice drumstick

Unfortunately there's no "off-the-shelf" 3" DP available really, it'll need to be custom or make it yourself dude.

worth replacing the brake hardlines to the rear while everything is out of the way, makes it a nice easy job.

That linkage balljoint is a PITA.

There is no replacement part for it, you can use the later 01E linkage balljoint, it needs trimming down to fit. Maybe you can reuse the later type of boot for it too? Or you can modify the linkage to take a uni-ball which makes changing gear feels like loading an anti-aircraft gun

Nice job dude, keep it up

Leave a comment:

-

Im itching to get it back together already!

Here's the plan! (for my sanity...)

- Steering Rack Service (£36 from Audi)

- New Fuel Lines inc braided hoses

- Replace a couple of brake lines, im being fussy!

- Check Engine Over (remove sump etc...make sure nothing nasty is there! Oil was clean as a whistle though

- Clean + Paint Engine Block

- Polish IM and Rocker Cover

- Clean Engine Bay, Paint a few little bits

- Fit new belts, tensioner and pulley

- New Handbrake cable

- Seam weld wishbones

- Paint subframes and wishbones in POR15

- Clean and paint gearbox and diff

- Service Koni shocks

- Fit all the new shiny, clean, non-rusty bits everywhere

not one bush is going unchanged! All hoses are getting replaced

Only annoying thing is that the front wing needs replacing and that will stretch the budget. So may be driving around with an odd coloured front wing for a while

decision to make on exhaust too...the downpipe's heat shroud is breaking up, not an issue. But do I get a 3" dp and exhaust now....or wait till its all on the road and running and have a fight putting a 3" dp in when the engine is in?

Leave a comment:

-

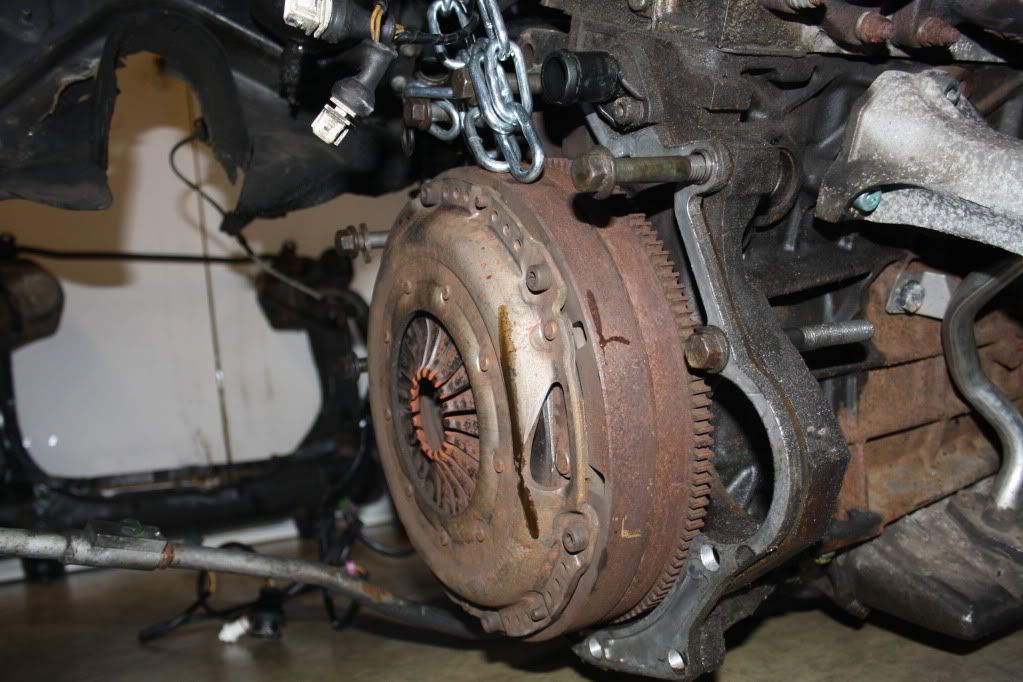

Made good progress this weekend. Engine, gearbox and front sub frame is out!

The bespoke crank locking tool worked pretty well. I got 6 inches of 2x2inch box section, cut a small slot the size of the ridge in the pulley in one end. This then slots into the pulley beautifully. Attach some stilsons, find an appropriate stack of magazines (Classic Tractor works well...others may be sufficient), big breaker bar and boom, your pulley bolt is un-done! I'd say its a use only once tool...

I'd say its a use only once tool...

Anyway, after that, we made good progress getting the engine out, all went well really!

no play in the turbo

Think this has broken though...any one know if this should easily come out?? its the gear linkage joint into the gearbox

Leave a comment:

Leave a comment: