Update

Managed to do a boost leak test today

First test

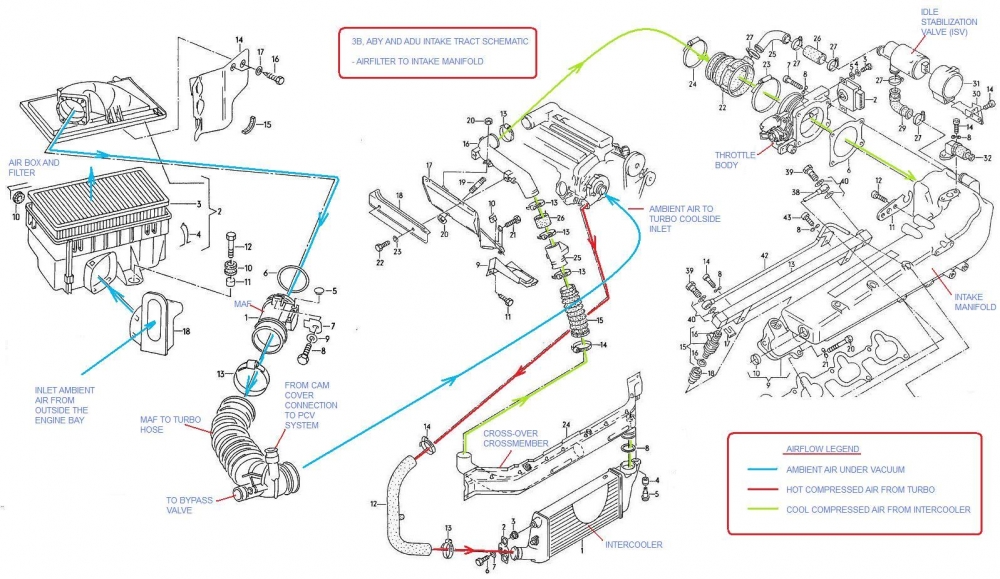

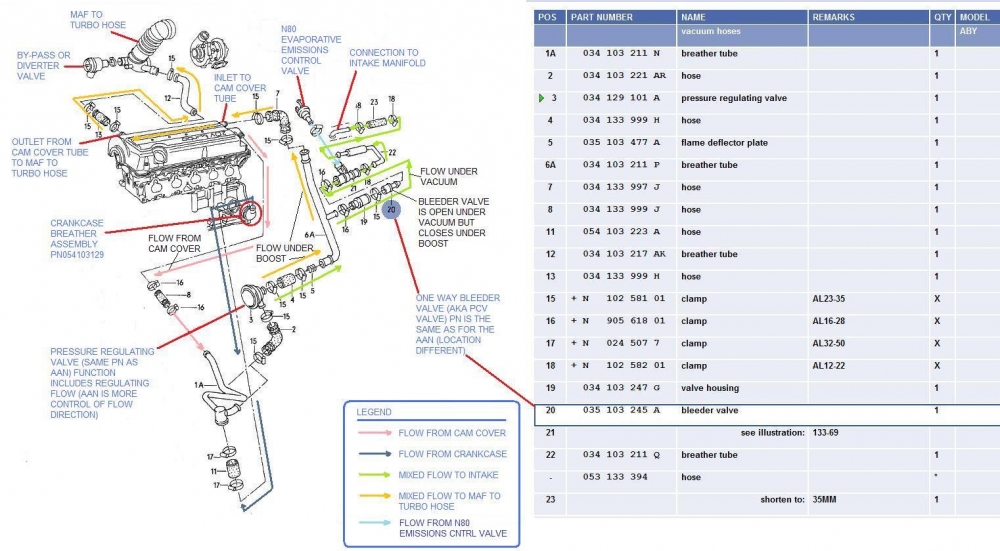

I plugged breather pipe on Maf hose, Intake hose after crossmember and fitted my spare boost gauge on the hose to the waste gate to monitor pressure.

1.4bar back to zero took approx 90secs

Second test I removed the plug on the intake hose and reconnected to the engine

wound up pressure to 1.4bar sprayed leak detector on hoses and only found small bubbles at lower ISV connection.

1.4bar back to zero took approx 60secs

Swapped out WGFV for new one.

Went for a drive and still around 1bar boost.

The car was stopped for 30min while visiting a mate tonight, found it was boosting better will try more test runs in the daylight tomorrow.

Pulled codes just now and found no faults so hopefully 00561 has been cured by the new lambda probe I fitted a month ago.

Checked throttle angle in vagcom

throttle angle 8.7% shut 96.1% WOT

Take it should be 100%?

Cheers

Steve

Managed to do a boost leak test today

First test

I plugged breather pipe on Maf hose, Intake hose after crossmember and fitted my spare boost gauge on the hose to the waste gate to monitor pressure.

1.4bar back to zero took approx 90secs

Second test I removed the plug on the intake hose and reconnected to the engine

wound up pressure to 1.4bar sprayed leak detector on hoses and only found small bubbles at lower ISV connection.

1.4bar back to zero took approx 60secs

Swapped out WGFV for new one.

Went for a drive and still around 1bar boost.

The car was stopped for 30min while visiting a mate tonight, found it was boosting better will try more test runs in the daylight tomorrow.

Pulled codes just now and found no faults so hopefully 00561 has been cured by the new lambda probe I fitted a month ago.

Checked throttle angle in vagcom

throttle angle 8.7% shut 96.1% WOT

Take it should be 100%?

Cheers

Steve

Comment