I have been trying to keep track of 4A0721261 clutch slave failure modes since mine failed before Christmas 2013. Finally got to see what was what Jan. 2014. (See link at the bottom of this post for the failure modes so far.)

Here is mine from Jan. 2014

Having recently posted questions on another forum about Mushasho's "naked" clutch cylinder actuation rod, I realized that if I still had my failed slave cylinder then I could take it apart and answer my question on how the rod was attached to the slave cylinder.

Mushasho's naked rod (insert rude joke here):

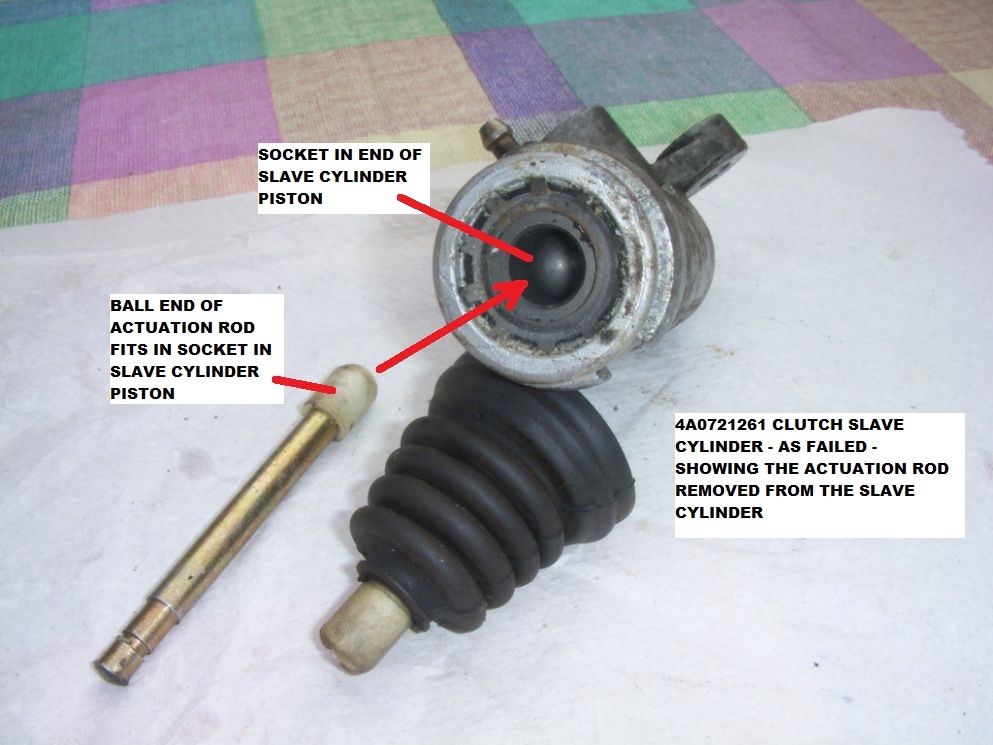

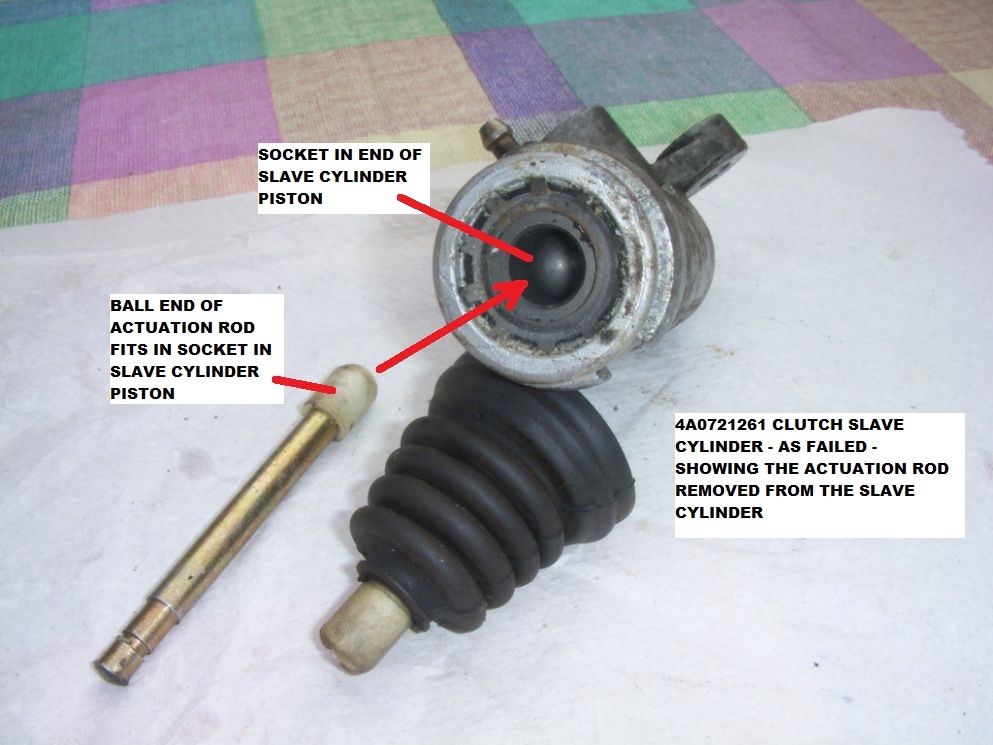

Okay here is my failed slave cylinder from this afternoon:

One side:

The other side:

With the boot off, exposing the actuation rod:

Better angle showing the end of the rod sitting in a socket in the slave cylinder piston:

The rod is NOT attached to the slave cylinder. It merely has a ball end that sits in the socket end of the slave cylinder piston. Held there, in part by the rubber boot (assuming the rod has not broken through the tip of the boot like mine did)

This photo shows how the actuation rod can be captured and held by a broken tip at the end of slave cylinder rubber boot:

Conclusion: For reasons not clear, the actuation rod of my slave cylinder caused the fatigue cracking of the plastic tip of the rubber boot allowing the rod to pass through the broken tip. Once out, the rod was disconnected from the slave cylinder piston and (very likely) twisted such that it would no longer push on the clutch throwout bearing activation arm.

Bottomline: Replacing the clutch slave cylinder might be a good idea after several years, even if it is not leaking. Either that or someone should develop a design for a brass or aluminum slave cylinder boot tip that would not fail.

REF: Clutch Slave Cylinder Failure Modes - http://forums.quattroworld.com/s4s6/msgs/316182.phtml

Here is mine from Jan. 2014

Having recently posted questions on another forum about Mushasho's "naked" clutch cylinder actuation rod, I realized that if I still had my failed slave cylinder then I could take it apart and answer my question on how the rod was attached to the slave cylinder.

Mushasho's naked rod (insert rude joke here):

Okay here is my failed slave cylinder from this afternoon:

One side:

The other side:

With the boot off, exposing the actuation rod:

Better angle showing the end of the rod sitting in a socket in the slave cylinder piston:

The rod is NOT attached to the slave cylinder. It merely has a ball end that sits in the socket end of the slave cylinder piston. Held there, in part by the rubber boot (assuming the rod has not broken through the tip of the boot like mine did)

This photo shows how the actuation rod can be captured and held by a broken tip at the end of slave cylinder rubber boot:

Conclusion: For reasons not clear, the actuation rod of my slave cylinder caused the fatigue cracking of the plastic tip of the rubber boot allowing the rod to pass through the broken tip. Once out, the rod was disconnected from the slave cylinder piston and (very likely) twisted such that it would no longer push on the clutch throwout bearing activation arm.

Bottomline: Replacing the clutch slave cylinder might be a good idea after several years, even if it is not leaking. Either that or someone should develop a design for a brass or aluminum slave cylinder boot tip that would not fail.

REF: Clutch Slave Cylinder Failure Modes - http://forums.quattroworld.com/s4s6/msgs/316182.phtml

I can't put that circlip inside to lock that rod

I can't put that circlip inside to lock that rod

Comment