Thanks for all the comments. Re wastegate - I tried to get the best flow design possible for the circumstances/space/setup, I hope it works out.. I'm sure it will. Can't wait to get it started to hear what it sounds like, but I'm a little way off that stage.

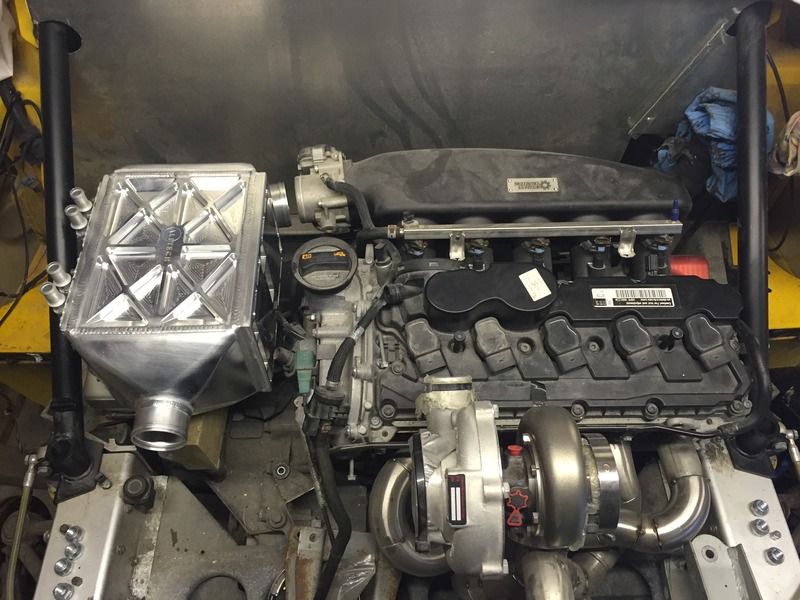

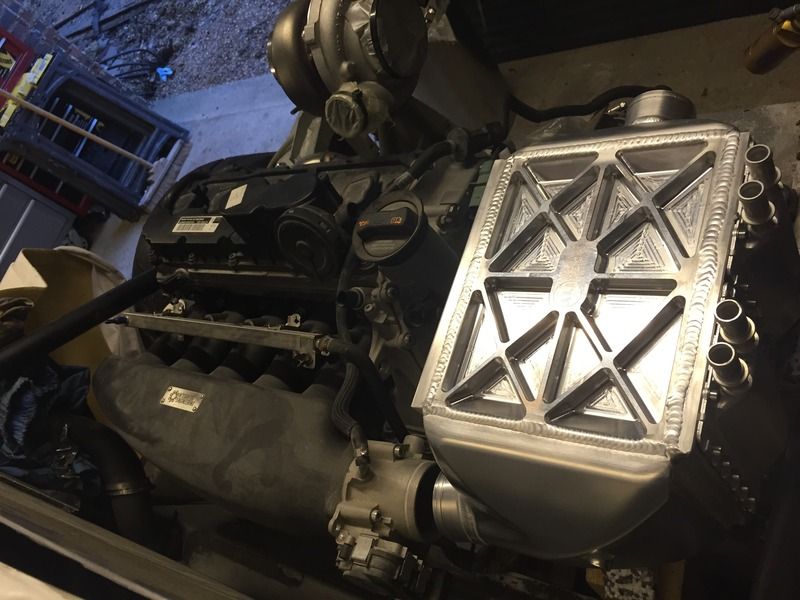

Don't have that luxury. It's placed in that position because that's the only way I can get it to fit and clear everything and having said that its friggin close in places ...!! The mounts are extremely stiff to try and minimise movement. Time will tell. But I will try and move weight about where possible, for example there will be 7 water radiators in the car, 4 of which will be up front. This will add some weight over the front wheels but I suspect it won't be as balanced from front to rear, left to right as in standard form. But then the standard car didn't have 600bhp!

Originally posted by Error404

View Post

Comment