I've just confused myself by reading this - I was under the impression that as long as the ECU could see the Hall sensor signal and it correlated with the crank position signal then the exact position of the dizzy did not matter?

Announcement

Collapse

No announcement yet.

possible cure for the 3B 'spark hop' issue?

Collapse

This is a sticky topic.

X

X

-

If the dizzy doesn't on the right possition, you need a stroboscopic lamp or some manual, the ecu will have a fault code, vag num. 00515, led num. 2113...and it's possible to have spark problems when you run fast, I think...but the engine run

Comment

-

Hmm, my car never started with code 2113, until i moved the dizzy round. I positioned the sensor directly in the middle of the window.

Engine runs and no 2113 fault code, but how do I know its timed up right?Panthero Coupé quattro 20vt

Indigo ABY coupé

Imola B6 S4 Avant

Comment

-

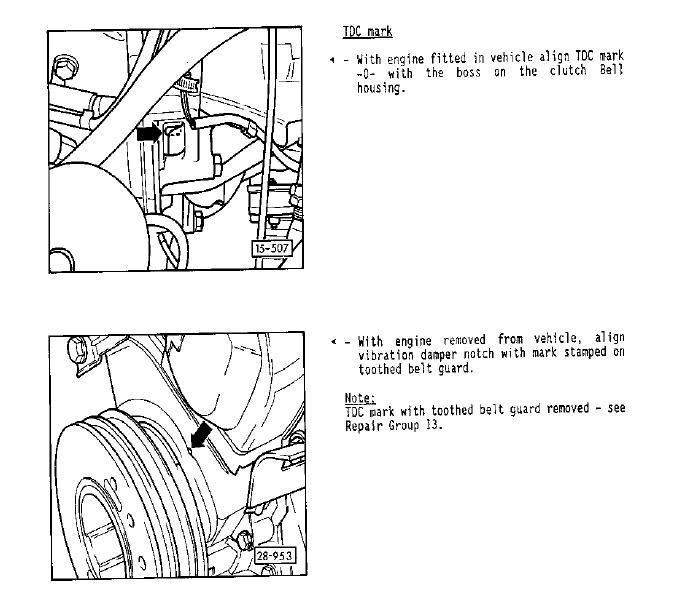

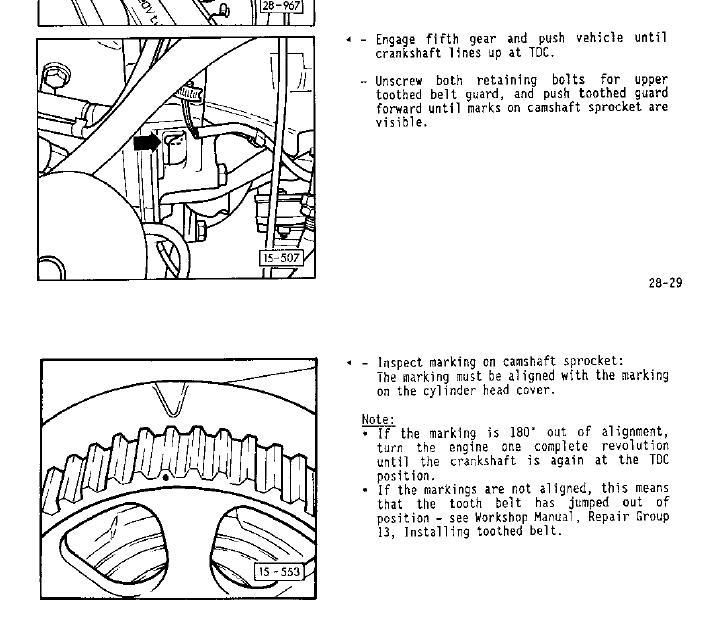

If its exactly on the marks, cams, dizzy and flywheel (there's a mark on the dizzy body and a mark on the hall sender shield) and you rolled it forwards in gear to take up any slack, then its correct, IMHO you can ignore the rest. (This is the way Mihnea told me to do it.)

Comment

-

As Newsh said, if all the marks are on the right possition, all it's good...firstly

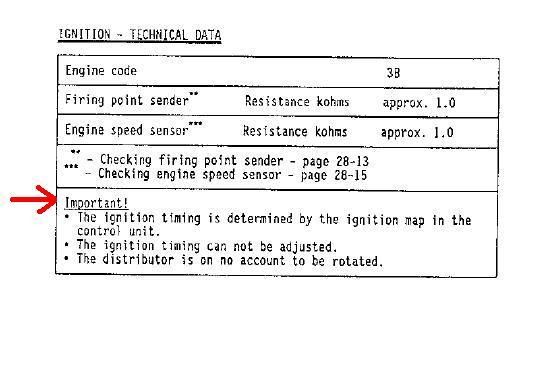

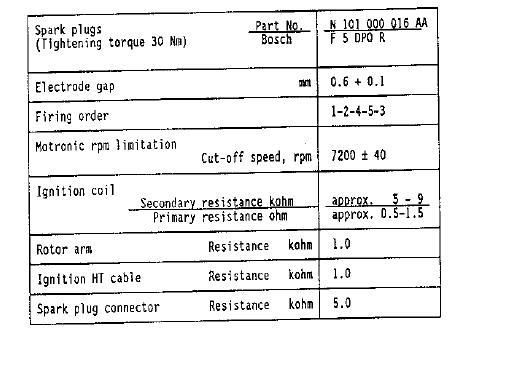

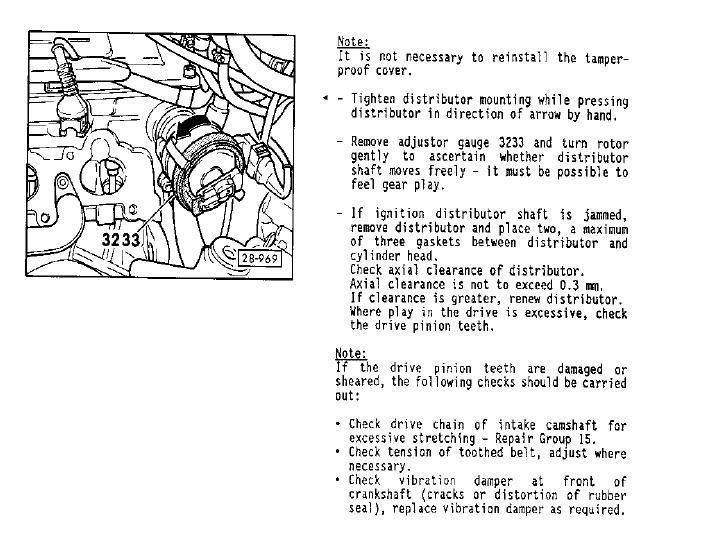

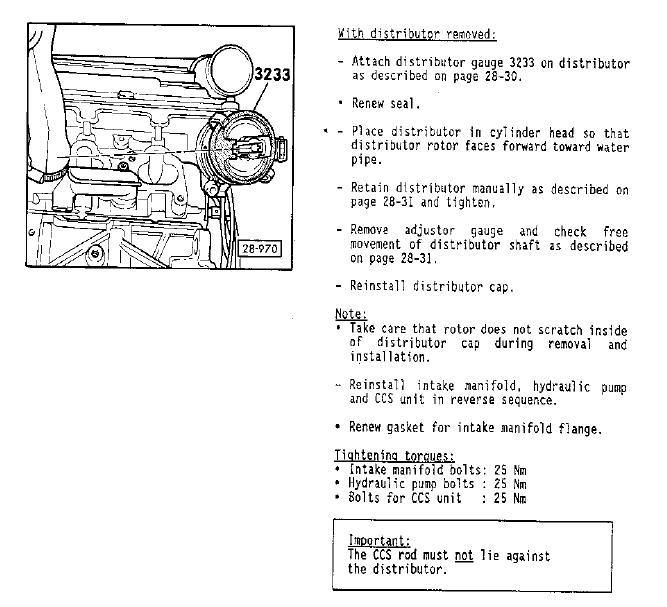

Some info about this, marks, resistance,ignition cables.... take a look at the important note....why audi allow some adjust on the dizzy?? I have this question on my mind many time ago...

Comment

-

Hi Guys,Originally posted by a4kquattro View PostThis information is 2nd hand, but it makes sense to me and thought I'd post it here to provoke discussion.

Most of you know about the issues with pre-ignition melting pistons on the 3B engine due to spark inside the distributor cap arcing to the wrong cylinder under high boost (where electrical resistance is greatest inside the cylinder).

The solution: Take a 10vt ignition rotor (which at 14mm is *wider* than the correct 3B rotor, bear with me here..) and trim off the leading edge of the tip making the new overall width 9mm. To visualize what I mean, here's a pic of an OE dizzy rotor where this is done:

discuss.

I cannot see the picture of the changed ignition rotor. What is wrong?

Comment

Comment