Shame you've got to alter the wastegate pipe, that transition into the DP was a work of art!

Announcement

Collapse

No announcement yet.

20V CQ Tidy Up

Collapse

X

-

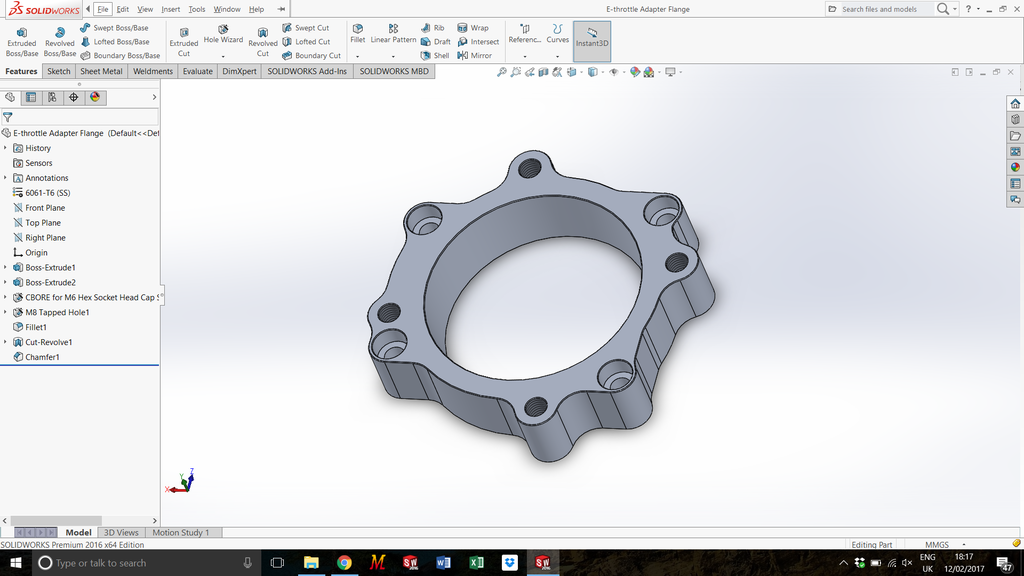

Oh God no...Originally posted by Error404 View PostPicked up a B8 S5 e-throttle off ebay for pence, so going to try and get that fitted so I can bin the ISV system and simplify the engine bay plumbing. Just need to make up a little adapter for it - more to follow.

Stay away from Siemens / VDO / Contintental throttle bodies. Bin that 06E garbage.

B8 S5/S4 3.0T Supercharged throttle body was plastic plate. 20 psi and that throttle plate is coming clean off. BTDT Circa 2012 and had to make the throttle plate out of aluminum.

In a 65 x 65 w/70mm (what that throttle body is) opening there are MUCH better throttle bodies to use:

- B5 S4

- Porsche 986

- VW Golf GTI 24V.

- Lamborghini 5.2 V10 etc

All manufactured by Bosch and all serviceable.

If it was me and considering the size of your engine and the turbocharger , I would go with a 75mm Bosch unit from a B5 RS4. Before you jump out of your seat and say "I don't have that loot" , they came in a bunch of VAG applications which have gone the waste side.

- Volkswagen Passat W8

- Audi D2 A8 4.2L

- Porsche 997 (not gone the waste side)

- Audi C5 A6 4.2L

- Audi RS3

- Audi TTRS

and so on and so forth.

On the plus side , if you are feeling OEM+ ish , you COULD use the RS3/TTRS throttle body cast elbow for that OEM look. It bolts right over the throttle body and is rather nice.

077 133 062 (A8/W8 Passat) or 07D 133 062 (RS4) is the throttle body you want otherwise 078 133 062 if you want to stay 65 x 65 w/70mm opening.

Either will be better suited for your needs and if you need one , I have a bunch (Over 150 pieces) of them.

Protip:

If you make the throttle body flange 2 piece , you will not need to clock the throttle body. I did the same thing when I made those 75+mm throttle bodies for the Sport Quattro guys.Last edited by Wizard-of-OD; 12 February 2017, 23:58.

Comment

-

Mtm rsr repOriginally posted by _ShurikeN View PostLongeron cut, no OEM filter box, DP modification... So why stay with cast exhaust manifold and not go tubular? 1990 2.2 20VT Audi Coupe Quattro

1990 2.2 20VT Audi Coupe Quattro

*Hx35/k26, MaxxECU, Wagner EM/IC *RS2 Recaro *4pot-Brembo *3" turboback *Treser *Koni/H&R

1990 Audi 200 20v Avant 2.2 20VT *7 Seater *Full electric gizmos

Comment

-

Thank all for the info Issam. I guess that's the reason it cost me about £8

I'll get an RS4 one as you suggest

Didn't go tubular as I already have the Wagner manifold - I planned to retain the RS2 air box but sadly it doesn't quite fit Panthero Coupé quattro 20vt

Panthero Coupé quattro 20vt

Indigo ABY coupé

Imola B6 S4 Avant

Comment

-

I pulled the engine today to investigate my low oil pressure issue. I did find it, but sadly it was an effect of a bigger issue.

The sump was full of grey cast iron sludge and the two forward thrust washers were in the bottom.

The rear thrust washers are worn to piss thin slivers

The crank, block and oil pump are written off.

The low oil pressure was caused by large side clearance in the pump gears as it had been slowly worn by the lapping paste the crank and main cap kindly provided.

This is as far as I got so far.

First thought was that I'd dropped a bollock and installed the thrust bearings backwards, but having fished the front ones out of the sump I was able to verify that they were in fact installed correctly. So now thinking there is a release bearing / pressure plate clearance issue that has been exerting constant pressure on the thrust bearings. Given the state of the clutch disc I had to change recently, I'm suspecting at this stage that the pressure plate is not as it should be - TBC.

No use crying over spilled milk I guess. I was planning to strip the bottom end to machine the semi-open deck anyway.

Luckily I have a spare ABY crank and block here so like a phoenix from the ashes, it will rise again.

Will carry out a full strip down next week to get to the bottom of it. Pics of the post mortem to follow.Panthero Coupé quattro 20vt

Indigo ABY coupé

Imola B6 S4 Avant

Comment

-

Very sorry to hear that Alex,hope you will get it sortedOriginally posted by Error404 View PostI pulled the engine today to investigate my low oil pressure issue. I did find it, but sadly it was an effect of a bigger issue.

The sump was full of grey cast iron sludge and the two forward thrust washers were in the bottom.

The rear thrust washers are worn to piss thin slivers

The crank, block and oil pump are written off.

The low oil pressure was caused by large side clearance in the pump gears as it had been slowly worn by the lapping paste the crank and main cap kindly provided.

This is as far as I got so far.

First thought was that I'd dropped a bollock and installed the thrust bearings backwards, but having fished the front ones out of the sump I was able to verify that they were in fact installed correctly. So now thinking there is a release bearing / pressure plate clearance issue that has been exerting constant pressure on the thrust bearings. Given the state of the clutch disc I had to change recently, I'm suspecting at this stage that the pressure plate is not as it should be - TBC.

No use crying over spilled milk I guess. I was planning to strip the bottom end to machine the semi-open deck anyway.

Luckily I have a spare ABY crank and block here so like a phoenix from the ashes, it will rise again.

Will carry out a full strip down next week to get to the bottom of it. Pics of the post mortem to follow.

Comment

-

That's unlucky Alex

It's not something I have heard of happening before on our motors, so something must have been well out of spec to have caused it. I have the integrated shells on mine, which some folk advise against, but they have been fine for many years of service. I guess if the tolerances are right, it's not going to be an issue which type you use. Constant lateral pressure from the clutch side would certainly wear our the thrust washers quickly. Hope you locate the culprit and understand what was wrong soon mate.Last edited by SteveH; 20 February 2017, 07:18.91 Modded 3B

14 A6 Avant Black Edition

Comment

-

Cheers guys. I used the recommended separate KS thrust bearings, and end float when I built it was 0.12mm so spot on. The clutch has always been very stiff, and I wonder if it's simply too stiff having overloaded the oil film. Having done some research last night it seems this is pretty common with other manufacturers when using heavily uprated pressure plates.

Anyway, I'm going to strip the rest of the engine down this week and see what is salvageable. I need to do a load of measuring and see if there is a clutch clearance issue. Then I'll get this spare block sleeved and bored and go again!Panthero Coupé quattro 20vt

Indigo ABY coupé

Imola B6 S4 Avant

Comment

-

Hate to say this but are you 100% sure you got the inline-5 thrust washers? I had a similar situation recently and it turned out I was supplied 1.8T thrust washers instead of AAN/etc thrust washers.Originally posted by Error404 View PostThe sump was full of grey cast iron sludge and the two forward thrust washers were in the bottom.

The rear thrust washers are worn to piss thin slivers

The crank, block and oil pump are written off.

Comment

Comment