@ Tommy200rs,

balancing knowledge and balance factors is something that has been passed down to me through other engineers through the years. What you'll find is that most engineers share information with each other in order to further their own knowledge and progress by the sharing of ideas and theories.

There is a few engineers handbooks that carry most old school popular balance factor configurations. For 90degree v's and narrow v's. once in a while you come across one that has not been published for whatever reason at which point you need to reverse engineer the process.

In such a situation you would first find the average small end and big end weights of the rod piston assembly. After which you start with the most common balance factor of 50%. You make up these bobweights and spin up the stock crank assembly. If it is not in balance you make up a 40% balance factor bobweight and spin up the assembly if it has gotten worse you try 60% etc... By process of elimination you can then usually determine the end figures.

As for manufacturers tolerances I've seen piston rod assemblies out of balance by as much as 20gramms at the small end on an externally balanced engine. Whereas internally balanced engines tend to be within 5-6 gramms at the small end. All comes down to what time of the day the components where made and balanced and whether the operator is having a bad day or not. An out of balance engine will still run just not smoothly and is more susceptible to heavier wear and tear resulting in a shorter serviceable life.

As for the specification of a balanced race setup each engineer has their personal preferences on that front. The ones that have modern digital technology to assist them tend to have much bigger tolerances as the machines that are used are the same that OEM manufacturers use. Where as those using old school dynamic balancers tend to be more particular and work to within 1gramm and where possible 0.5gram.

Then the argument starts about oil deposits on the rotating assembly changing all the weights as the minute you add oil to the bottom of your piston one may be a couple of grams heavier compared to the rest so was it really worth balancing to within 1 gram?

On an I5 if it is perfectly balanced you should be able to do the Bentley trick which is take a 20p coin and place it on it's edge on the rocker cover of the engine whilst running. It should then stay perfectly balanced on it's side as you rev the engine smoothly through the lower rev range.

balancing knowledge and balance factors is something that has been passed down to me through other engineers through the years. What you'll find is that most engineers share information with each other in order to further their own knowledge and progress by the sharing of ideas and theories.

There is a few engineers handbooks that carry most old school popular balance factor configurations. For 90degree v's and narrow v's. once in a while you come across one that has not been published for whatever reason at which point you need to reverse engineer the process.

In such a situation you would first find the average small end and big end weights of the rod piston assembly. After which you start with the most common balance factor of 50%. You make up these bobweights and spin up the stock crank assembly. If it is not in balance you make up a 40% balance factor bobweight and spin up the assembly if it has gotten worse you try 60% etc... By process of elimination you can then usually determine the end figures.

As for manufacturers tolerances I've seen piston rod assemblies out of balance by as much as 20gramms at the small end on an externally balanced engine. Whereas internally balanced engines tend to be within 5-6 gramms at the small end. All comes down to what time of the day the components where made and balanced and whether the operator is having a bad day or not. An out of balance engine will still run just not smoothly and is more susceptible to heavier wear and tear resulting in a shorter serviceable life.

As for the specification of a balanced race setup each engineer has their personal preferences on that front. The ones that have modern digital technology to assist them tend to have much bigger tolerances as the machines that are used are the same that OEM manufacturers use. Where as those using old school dynamic balancers tend to be more particular and work to within 1gramm and where possible 0.5gram.

Then the argument starts about oil deposits on the rotating assembly changing all the weights as the minute you add oil to the bottom of your piston one may be a couple of grams heavier compared to the rest so was it really worth balancing to within 1 gram?

On an I5 if it is perfectly balanced you should be able to do the Bentley trick which is take a 20p coin and place it on it's edge on the rocker cover of the engine whilst running. It should then stay perfectly balanced on it's side as you rev the engine smoothly through the lower rev range.

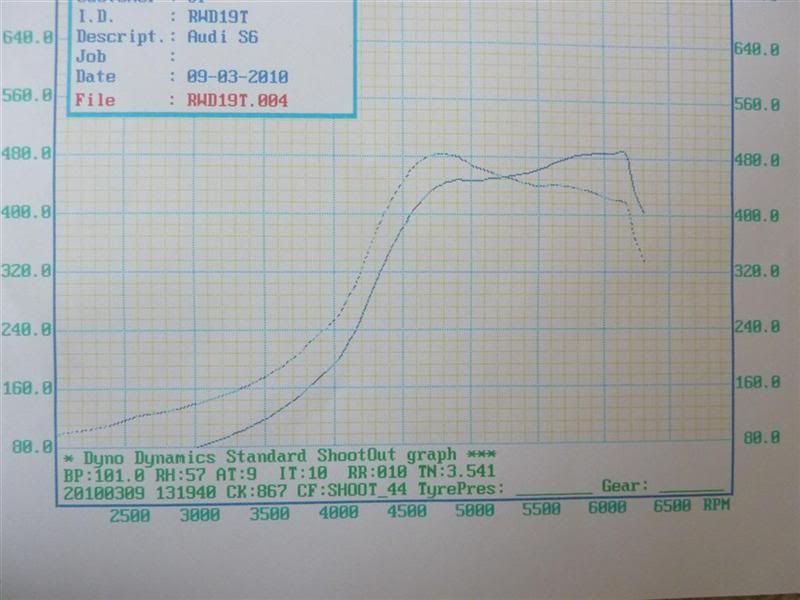

Thanks for the warning - really looking to maximise the efficiency of the stock set-up and using Paul's homefries chip, midrange driveability and response over top end power for me although 301bhp has a nice ring to it on the K24 - as you say how long it lasts is a different matter

Thanks for the warning - really looking to maximise the efficiency of the stock set-up and using Paul's homefries chip, midrange driveability and response over top end power for me although 301bhp has a nice ring to it on the K24 - as you say how long it lasts is a different matter

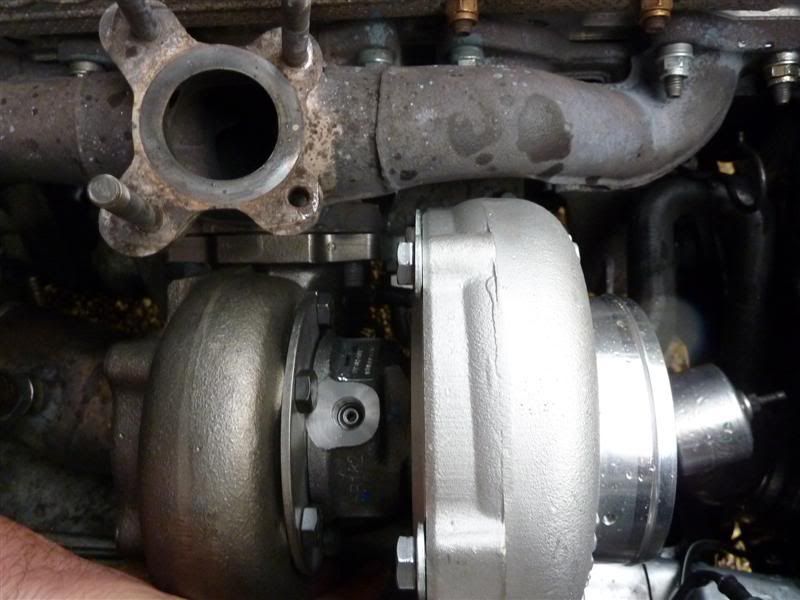

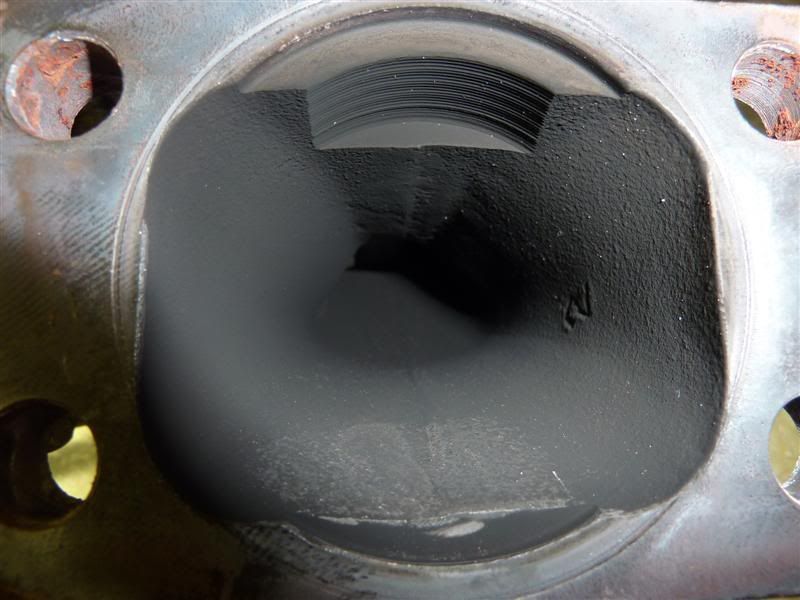

That compressor intake looks like it could swallow a ruddy planet!!

That compressor intake looks like it could swallow a ruddy planet!!

Comment