You do both it doesn't weaken the block, I've seen it done and have pics of an I5 block and head done up with it. Repo is the man to speak to he has the tool to do it to the correct depth

Announcement

Collapse

No announcement yet.

The '2 ton bugswatter' - back for a gentle stroke

Collapse

X

-

Machining is not the issue the cnc mill at my mates is programmed to the correct settings for either block or head. My only concern is that the tensile strength of a stock cast grey iron block isn't all that great. So I tend to prefer not eating into it unnecessarily strength wise. In the same token if using ductile liners for increased borewall strength it becomes less of an issue as they are 100,000psi tensile compared to the stock casting which is 30,000psi tensile.Originally posted by Jamo View PostYou do both it doesn't weaken the block, I've seen it done and have pics of an I5 block and head done up with it. Repo is the man to speak to he has the tool to do it to the correct depthUrS6 Stroker + HTA3586 =

Comment

-

Can you go into some depth about balancing your crank?

Like the correction factor used on your bob's and what you mean by internally balancing the crank.

People say the i5 crank is a 50% correction factor but so far no one has given me a understandable explination how this factor is calculated.

Many thanks Baz.The ONLY S2 Golf!

http://www.s2forum.com/forum/showthread.php?t=19402

10.42@138mph

https://m.youtube.com/watch?v=0wnkkOfFpXg

Comment

-

Grabed from here...Originally posted by gnutz2 View PostCan you go into some depth about balancing your crank?

Like the correction factor used on your bob's and what you mean by internally balancing the crank.

People say the i5 crank is a 50% correction factor but so far no one has given me a understandable explination how this factor is calculated.

Many thanks Baz.

http://www.rpmmachine.com/engine-balancing.shtml

Internal or External

With "internally balanced" engines, the counterweights themselves handle the job of offsetting the reciprocating mass of the pistons and rods. "Externally balanced" engines, on the other hand, have additional counterweights on the flywheel and/or harmonic damper to assist the crankshaft in maintaining balance. Some engines have to be externally balanced because there isn’t enough clearance inside the crankcase to handle counterweights of sufficient size to balance the engine. This is true of engines with longer strokes and/or large displacements.

If you’re rebuilding an engine that is internally balanced, the flywheel and damper have no effect on engine balance and can be balanced separately. But with externally balanced engines, the flywheel and damper must be mounted on the crank prior to balancing.

You should find out what type of engine balance you have (internal or external), and be cautious about indexing the position of the flywheel if you have to remove it later for resurfacing. Owners of externally balanced engines should also learn about installing different flywheels or harmonic dampers and how it can upset balance.Carlos.

On the look out for less bits for my s2 saloon project. Now supporting myself by shooting for my food. www.airgunforum.co.uk

Comment

-

^^^^That covers the initial portion of it, long and short of it for an engine that may see a flywheel change in it's lifetime is better of being internally balanced.

As for balance factor to make up the bob weights is as follows.

Each bobweight (1 for each big end journal) is calculated by

100% of the big end weight of the rod incl big end bearings + 50% of the weight of the small end of the rod incl wrist pin, c-clips/spiral locks, piston and rings.

That is for an inline 5 whereas for other engines that require different balance factors all you do is change the percentage of the small end total to reflect it.UrS6 Stroker + HTA3586 =

Comment

-

Guess I'm just being overcautious belts and braces then.Originally posted by Jamo View Postthe cars it was done on is running 700 bhp I think it's safe I believe Pravoola is also running it on his 1000 bhp car.

I believe Pravoola is also running it on his 1000 bhp car. Saying that I would have less of an issue on a diesel block as they tend to have more structural thickness in their castings.

UrS6 Stroker + HTA3586 =

Saying that I would have less of an issue on a diesel block as they tend to have more structural thickness in their castings.

UrS6 Stroker + HTA3586 =

Comment

-

Could you reveal what is your information source / theoretical backround (bobweight calc 5er) or written documents about that, references for uneven cylinder engines (2 or 3 dimensional) balancing ?Originally posted by RWD19T View PostEach bobweight (1 for each big end journal) is calculated by

100% of the big end weight of the rod incl big end bearings + 50% of the weight of the small end of the rod incl wrist pin, c-clips/spiral locks, piston and rings.

That is for an inline 5 whereas for other engines that require different balance factors all you do is change the percentage of the small end total to reflect it.

How to end up to that "100% + 50%" as good approximation ?

The subject has been interesting. There are earlier threads also covering this area in S2 forum in relation to lightening also http://www.s2forum.com/forum/showthread.php?t=21805 . .... In search of the 5er saga of smoothness & rev nirvana. Where is the final proven T5 math formula and preferably in excel. Check one example 7, open the details box also and enjoy the math http://www.codecogs.com/reference/en...tia_forces.php

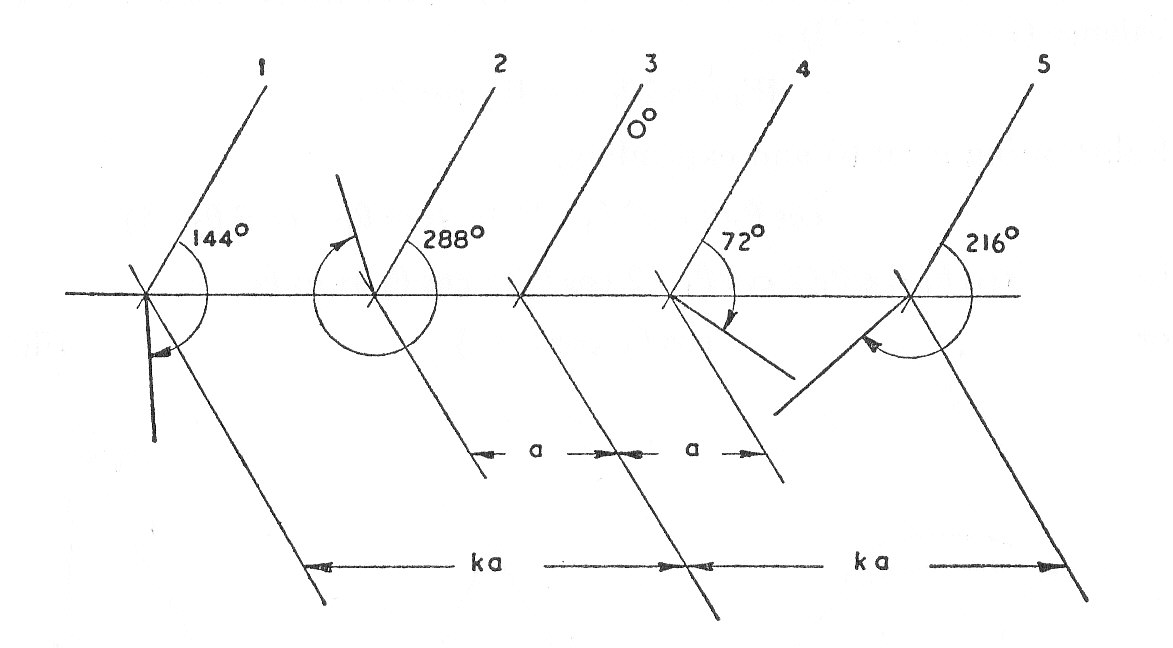

a pic:

" By sketching suitable vector diagrams verify that the engine is in balance for primary and secondary forces. Show in a similar manner that the engine is in balance for primary couples if the distances of the outer and inner cylinders from the central cylinder are in the ratio k=1.618 and that the out-of-balance secondary couple then has the following magnitude " :

But how to do the balance in practice ....

See Chapter 8 of "The Internal Combustion Engine in Theory and Practice".

http://books.google.com/books?id=mX1...age&q=&f=false

where the 5er vibrations are

http://www.autozine.org/technical_sc...ne/smooth2.htm

" both ends of the engine will vibrate up and down with respect to the engine center. " ... but Audi did not put the balancing shaft there. why not ?

When big volumes of engines are made and spare parts needed the parts need to be interchangeable. So how crap is stock and how good is fine tuned ?

the stroked big five needs definitive balancing

http://upload.wikimedia.org/wikipedi.../58/5S50MC.jpg

The water grooves were in the 80s in the factory race 10v engines. I have seeen one MRQ engine where done (that rare block now in Norway!)

Keep on doing the good work in this thread and tell then the experiences how softly it revs !Last edited by Tommy200rs; 28 March 2010, 15:47.

Comment

Comment