Was is the right word, now they are impossible to find. They have a valve which is activated at around 1800rpm which changes the mount stiffness.

Announcement

Collapse

No announcement yet.

A6 Nogaro Blue TDI restomod

Collapse

X

-

You can also use K16-6721. It's much bigger turbo than K14-6707. Compressor and turbine side.Originally posted by radi_nrj View PostHowever I plan to get rid of the stock K14 6707 and replace it with K16 6711 from Audi 100 2.5, it should be a direct swap. I already bought the K16 but still wonder what to do with it, just rebuild it or upgrade it with a billet compressor wheel.

We used this turbos at Fiat Uno Turbo years ago :-D

My father has this turbo in his Uno, running around 150hp but more is possible...

Very robust turbos, do the upgrade to Billet wheel!

I hope you check the chassis next to the steering rack, is offen broken at the V8 under the "enforcement" sheet.

Can look for pictures when you need.

Good luck!

- 1 like

Comment

-

-

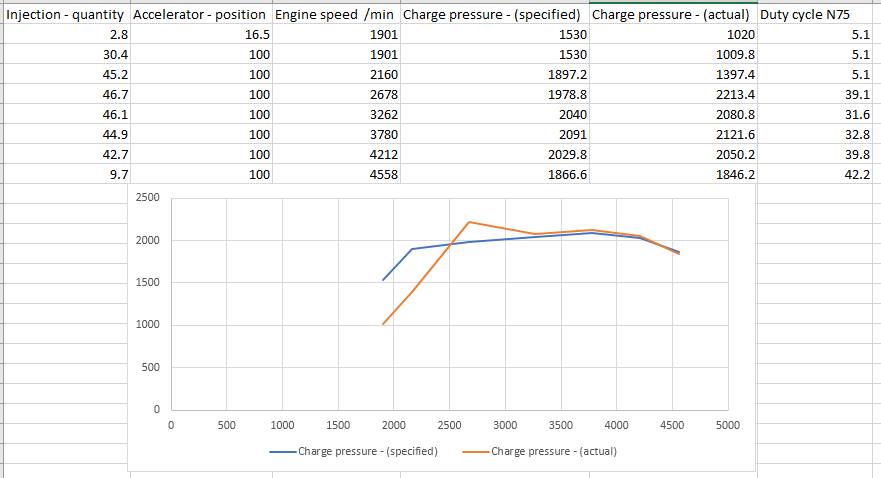

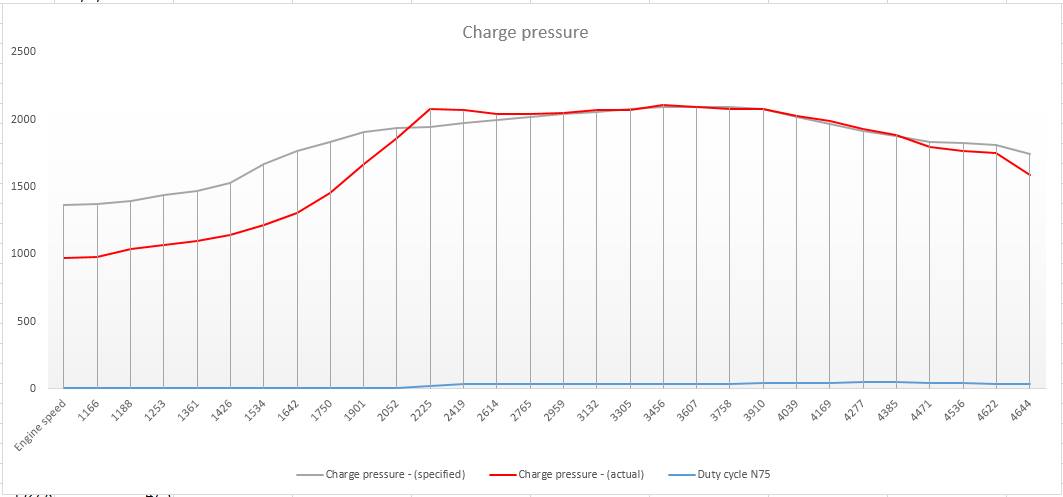

We have Boost

And one more grapgh from 1000rpm

I did a log from 2000 to 4500rpm and you can clearly see how laggy those old engines are, I floor it on 1900rpm and it still spools till 2500rpm

It was all fun and games for several days tull yesterday when I've noticed white smoke when I accelerate, and this morning 300mL of coolant were missing.

Now I have another upgrade on my mind - ARP studs and MLS gasket

Here I was cougnt in action while fixing a friend's UrS6 wiring.

Last edited by radi_nrj; 12 April 2018, 17:32.

Last edited by radi_nrj; 12 April 2018, 17:32.

Comment

-

-

It is always fun with those old cars. Hello white smoke... It is not oil, and it is not coolant. Now lets see which is the culprit. My bets are 80% on the injection pump and 20% on the injectors.

It ran a 17.2 where it should do16's

So the injectors and the pump got out. The injectors were sent to a specialit to be refurbished and the pump will be checked when I come back from vacation

Last edited by radi_nrj; 25 May 2018, 18:17.

Last edited by radi_nrj; 25 May 2018, 18:17.

- 1 like

Comment

-

It has been a long time but had some other other things to do and the car was left aside. So we now have one fully refurbished fuel pump, new DTP injector nozzles and the car runs even worse. it does not smoke so much but it lacks even more power. However after almost a year and a half I managed to assemble the rear hubs and at least i'll get the S6 rear brakes fitted before winter (It may lack power but it has to stop )

)

in the meantime I'm helping a friend restoring his 2.2T 6 speed manual S4

Comment

-

-

I would suggest check for signal to/from from No.3 Injector lift sensor. The wiring from it is small and every time injectors are removed you risk damaging it. BTDT due to careless injector "specialist".

Pump timing can be fun on these engines. I wouldn't waste time using a dial gauge in the *** of the pump. Line up the pump marks as per factory, and check with VCDS once run up to temp. Also, disconnect the temp sensor at hot idle and you will hear the engine sound a wee bit different until reconnection.

On my last C4 (AAT) I ended up with the pump body's marks noticeably "over advanced" whilst VCDS was spot on, and she pulled like a trooper.Last edited by 5cylinderman; 25 June 2019, 14:17.

- 2 likes

Comment

-

Hello, I've followed your topic for a long time. I also have Ael. As for your problems with injectors - I recommend the tips of the Polish company WZM - they produce several types: 0.210 -OEM AEL 140hp 0.216 - OEM VW T4 150hp Or larger tuning versions: 0.230 and 0.260. These tips are of good quality and are cheap about 75 PLN / 17 EUR / pcs. https://allegro.pl/kategoria/czesci-...h=seng-v6-b118 My colleague from www.audi-C4.pl has a daily 300hp ael. And this is how is fly. https://www.youtube.com/watch?v=_zRI...ature=youtu.be

- 1 like

Comment

-

Hi Guy, unfortunately the engine got diagnosed with one of the few infant illnesses of the 5 cyl diesels. We have a case of block warping and the crankshaft center line. Is no longer a line, more like a curve. Currently I'm saving for full engine rebuild

Comment

-

The engine is still toast, but I'm spending money on options.

Going to the bank tomorrow to wire some money and waiting for delivery

d5f1e813750817b1.jpg

- 1 like

Comment

Comment