Curious, from the heads i have seen i thought the earlier were better castings. Certainly the 93 ABY head is horrible, the mould had shifted along the intake ports and by cyl 5 there was a step where it meets the valve seat due to lack of material. The 93 AAN head dosent appear to have the same issue, and the 7A and 3B heads both have plenty of meat around them. I also noticed neither the 7A or 3B head have any cracks around the spark plug holes. The 7A i can understand but the 3B head came off a 400bhp motor crack free.

Announcement

Collapse

No announcement yet.

The '2 ton bugswatter' - back for a gentle stroke

Collapse

X

-

Like I say I really do think its luck of the draw, I've had cracked 3B heads, mint ADU's.

My 7A was cracked on 3 plugs and one so bad we had to machine out an exhaust seat. Weld it up and fit a new seat.

My issue lies with the irregularity as the casting gets close to the waterways as it causes thin spots on the walls when pushing the port sizes.UrS6 Stroker + HTA3586 =

Comment

-

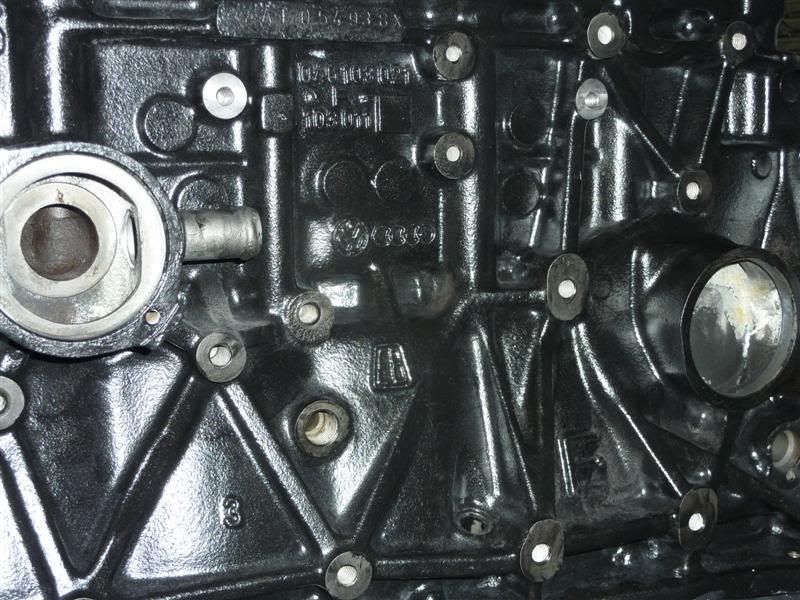

Well the joys of the knock sensor saga are sort of resolved, we've managed to machine down two blanks and tap them for knock sensors using an angle head on my mates mill. It's placed the knock sensors in the correct location relative to 1,2 and 3 & 4 and 5. Also the correct distance from the main block face. However the decision to go aftermarket management has now been accelerated as we now have different block density, capacity and size meaning the knock resolution is going to be out on the stock management. Personally I do not wish to push the boat out with one of the main safety features not functioning correctly.

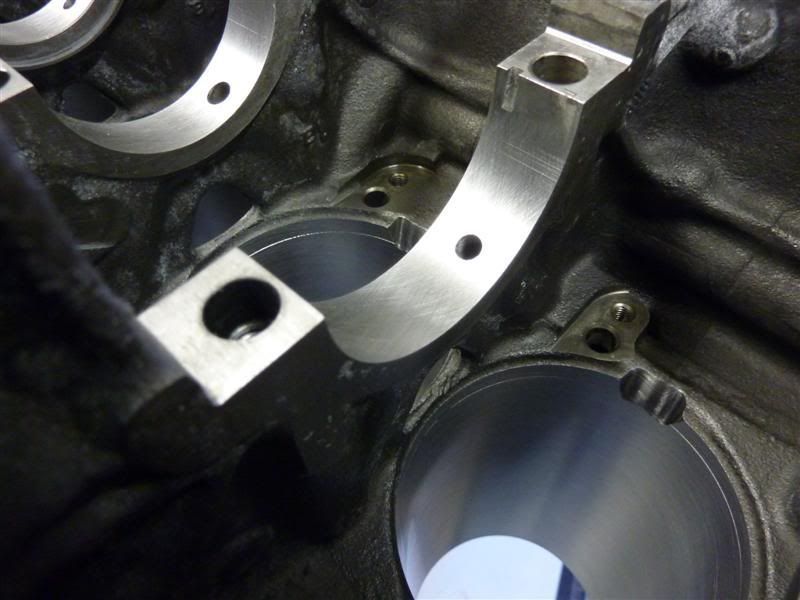

Now that I knew that all the niggly issues had been resolved I went ahead and did a couple of dry builds to work out by how much the bores had to be cleared for the Pauters.

Both wet and dry oil clearances double checked, a nice tight 2.5 thou compared to my usual desired 3 thou thanks to the big end broaching allowing for extra oil removal at higher rpm.

Last of the piston and rod assemblies going in.

Rods torqued up using the stretch method, despite the instructions being quite clear with regards to 60ft/lb using motor oil and the digital torque wrench being recently calibrated, the 625 ARP's still had to go all the way to 70ft/lb using ARP lube if proper stretch was to be achieved at the lower end of the range even after burnishing the threads.

Gratuitous shot

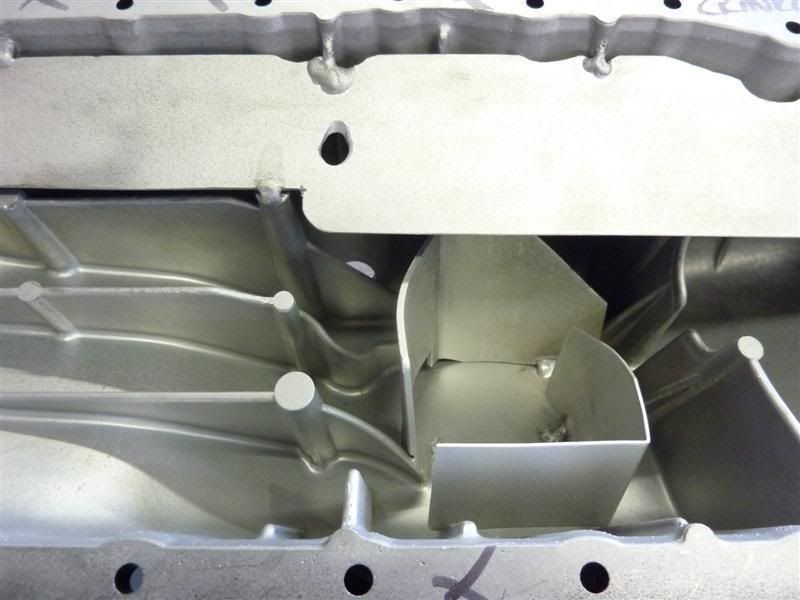

Stock AAN windage tray modified to clear the studs and oil pick up fitted.

12mm ARP headstuds from 034 fitted

Headgasket checked for clearance, as suspected one of the rivets fouls so I've drilled this out.

Head on and torqued down, onto the last two hurdles now working out what combination of modified timing covers I'll be using and making a baffled sump.

That's it for the week now, I've dropped of my sump to another of my mates who has my TIG at the moment as he is much better than me and has to do a load of -an weld on bungs for the breather system for me along with the baffled sump. All being well the -an fittings will all arrive on Tuesday for him to weld onto the required parts by wed evening as he is on holiday as of thurs morning.

If everything goes smoothly the next update will be after we pull the engine on the 28th at my mates paint shop in Luton/Dunstable Quattro Coachworks so he can do the bay whilst the engine is out

Just need to sort out a loan car now for a week as it's my daily and I have no spares UrS6 Stroker + HTA3586 =

UrS6 Stroker + HTA3586 =

Comment

-

Its really coming together now

Was the effective torque on the rod ARPs pretty much 70ft/lb across the board to achieve the right stretch?

Bit worrying as not many DIYers have access to a stretch gauge

What are the plans for the sump? Check flaps? Panthero Coupé quattro 20vt

Panthero Coupé quattro 20vt

Indigo ABY coupé

Imola B6 S4 Avant

Comment

-

I think this is down to the 625's being just ridiculously hd bolts as they all came in between 69-70ft/lbsOriginally posted by Error404 View PostIts really coming together now

Was the effective torque on the rod ARPs pretty much 70ft/lb across the board to achieve the right stretch?

Bit worrying as not many DIYers have access to a stretch gauge

What are the plans for the sump? Check flaps?

When I use ARP 2000's which most H-beams are supplioed with and stock pauters too 50ft/lb = 5 thou stretch, 55ft/lb = 5.5 thou. It's a very consistent reading when using the ARP lube and the bolts have been burnished properly.

Sump design I've decided not to use check flaps for two reasons.

1 - You need to do some hefty cornering to fill the pick up area so gentle town and country lane school run driving will not supply enough oil to the pick up area at long durations of traffic.

2 - Don't like the idea of anything down there having the ability to come of and make a mess of things.

Instead I've opted for a very simple modification over the standard baffling that assists the windage tray. Stops oil surging into the block breather hole. Allows free flow of oil around the pick up pipe area and slows the oil down from going away from the pick up pipe under hard cornering.

I'll post the pictures up on mon eve when it's finished.UrS6 Stroker + HTA3586 =

Comment

-

Beatiful work as usual.

Interested to see that, sounds good.Originally posted by RWD19T View PostInstead I've opted for a very simple modification over the standard baffling that assists the windage tray. Stops oil surging into the block breather hole. Allows free flow of oil around the pick up pipe area and slows the oil down from going away from the pick up pipe under hard cornering.

I'll post the pictures up on mon eve when it's finished.Current-2004 Impreza PPP wagon

Sold-92 3B coupe-RS2+, 996s, konis, rear torsen, forged rods........

Sold ABY-stock

Comment

-

Well didn't get round to taking a picie of the sump as it had to be rushed of to the powder coaters to keep everything in the correct time frame. So I'll do this when it gets back and bolted onto the engine.

I've also had to Junk the 3B timing belt set up as my auxilary brackets of the AAN don't clear the waterpump, so swapping over the oil pump later today and drilling the three holes I need for the tensioner. New water pump on Tues morning and she'll be ready to time up and seal up.

Other than that the ever declining spiral of the engine swap has commenced and there is absolutely no turning back now as you'll see from the pics.

Got to my friends paint shop Quattro Coachworks in Luton/Dunstable bright and early at 8am yesterday. After moving a freshly reconditioned UR 20v out the way to get mine in the work shop the work commenced.

Somewhere around 9:40 in the morning we were ready for the real job at hand, the engine and box was ready to come out.

Once the engine was out I discovered that I'd managed to dodge a bullet and a half

Also I may have to tone down my driving style as both engine mounts appear to have separated and torn loose I just cannot bear going to solid mounts. Anyone know of an alternative uprated one?

I just cannot bear going to solid mounts. Anyone know of an alternative uprated one?

Engine out and completely stripped other than the exhaust manifold and turbo. Heads spoken for but after inspection the bottom end will be up for sale in the for sale section. Also discovered a faulty central water manifold gasket which explained the ever so slight a smell of coolant I sometimes noticed and the water streaks down the block.

9:30pm last night as we called it a day

Have to say the day was emotional & exhausting, it didn't help that in the middle of it I had to take a 1.5hr round trip to get a loan car. Which was probably the most emotional part purely down to the traffic jams turning it to a 2.5hr experience

Have to say to Ish at Quattro Coachworks for being probably the most efficient I've ever seen anyone strip what has to be a seriously cluttered engine bay.

to Ish at Quattro Coachworks for being probably the most efficient I've ever seen anyone strip what has to be a seriously cluttered engine bay.

Tue morning the car will get prepped ready for painting the bay during the week. Presuming everything goes to plan the stroker will be sitting in it's new home by the end of next saturday ready to be mocked up for it's new breather system and finish sometime during the following week UrS6 Stroker + HTA3586 =

UrS6 Stroker + HTA3586 =

Comment

-

Nice progress!

Comment

-

you could try the 034 street version of the engine mounts, they are the only in between solution. I couldnt use them because of the rise of the engine they cause and make the wagner manifold unable to clear the hood, esp. with the phenolic spacer.

good progress indeed! It's easy when you know how...

Comment

-

Engine bay is being build back up tomorrow. I still have to bolt a couple of bits to the lump. Pick some fresh jubilee clips up. And hoping to either drop her in late tomorrow night or Tue. After which its a couple of evenings of cosmetics to be ready for driving next weekend when I have to hand the loan car back.

I'll post an update with some pics tomorrow morning but with an average of 4hrs of sleep a night for a week coming up against a couple of challenges all I can say it's been an emotional week UrS6 Stroker + HTA3586 =

UrS6 Stroker + HTA3586 =

Comment

-

OK coupled with kids half term (some poor planning on my behalf) heavy workload and a couple of last minute mods 2 weeks of late nights have finally come together.

Only a couple of pics as I wish to finish the bay a 100% before showing it of other than to the fortunate few who have befriended the correct facebook users and followed the mobile upload progress as it happened

First of the engine bay finally prepped ready for primer courtesy of Ish and crew at Quattro Coachworks

Next the picture that I keep meaning to post of the sump internal mods. An extension to the windage tray to stop direct oil going up the breather and an encapsulation method to prevent sideways slosh of oil under hard cornering and acceleration.

Engine almost in it's final stages ready for the gearbox

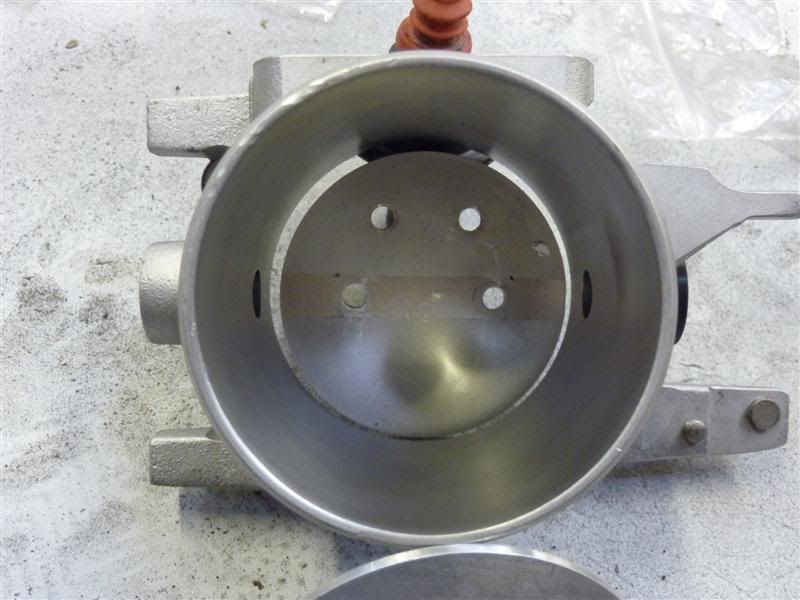

And a last minute decision to overbore the throttle body for an extra 10% surface area and removal of the cheese wedge.

So after 2 weeks of hard graft we got her running on saturday night to check for leaks, with the final assembly on Sunday to drive out the workshop at 9pm at night yes an early night for once.

I spend most of Monday running errands to get parts and bits for work and drove to the TT shop in Bedford to get my tracking done as the whole front end had been of. Surprisingly my camber and caster was spot on despite having adjusted it by eye

Couple of visits to friends in the evening and by the time I got to MRC this evening managed to do several oil changes and clock up a decend mileage ready for a low boost wastegate pressure map.

We ended up with 1 bar of boost at 3500rpm tailing of to 0.85bar at a redline of 7000rpm. The power curve showed she wanted to carry on making power past the 7000 mark but we decided to hold back until the semi synthetic is changed for fully synthetic after some more miles. As we were still bedding in the triple plate clutch it was also a wise time to call it a day on the boost levels until later in the month.

I'll let the vid Doug did do the talking but lets just say I'm really really happy with the results

http://www.youtube.com/watch?v=3z_dg...&feature=feedu

I have to say if it wasn't for a solid crew of friends and colleagues in various trades this would not have been pulled of in 2 weeks.

So first of a thankyou to my mate Marcus for sorting me out a loan car while my daily was of the road.

The crew at Quattro Coachworks for their hard work and staying many a late night helping me finish the car, seriously 2-3am is well beyond the call of duty when you have to be up to re open at 7am!

My Mate Darren who pulled some late after hr shifts doing the last minute ally welding mods that were needed for the breather system.

Precision Engineering in Markyate, who machined up elaborate custom components faster than you could purchase of the shelf units through mail order.

Will @ VRS for sorting a set of Engine mounts when TPS/Audi where on Back order.

And Doug and Mihnea @ MRC for pulling a late one tonight to put a nice low boost map on the car so I can carry on shaking her down.

There is probably others but I'm shattered ready for bed and can't remember so apologies if I didn't mention you. UrS6 Stroker + HTA3586 =

UrS6 Stroker + HTA3586 =

Comment

-

Nice result JP.

Comment

Comment