It looks like an interesting project. Very time consuming. Good luck.☺

Announcement

Collapse

No announcement yet.

Audi quattro S1 E2

Collapse

X

-

Moved onto working on the other side at the base of the A pillar same process as the first.

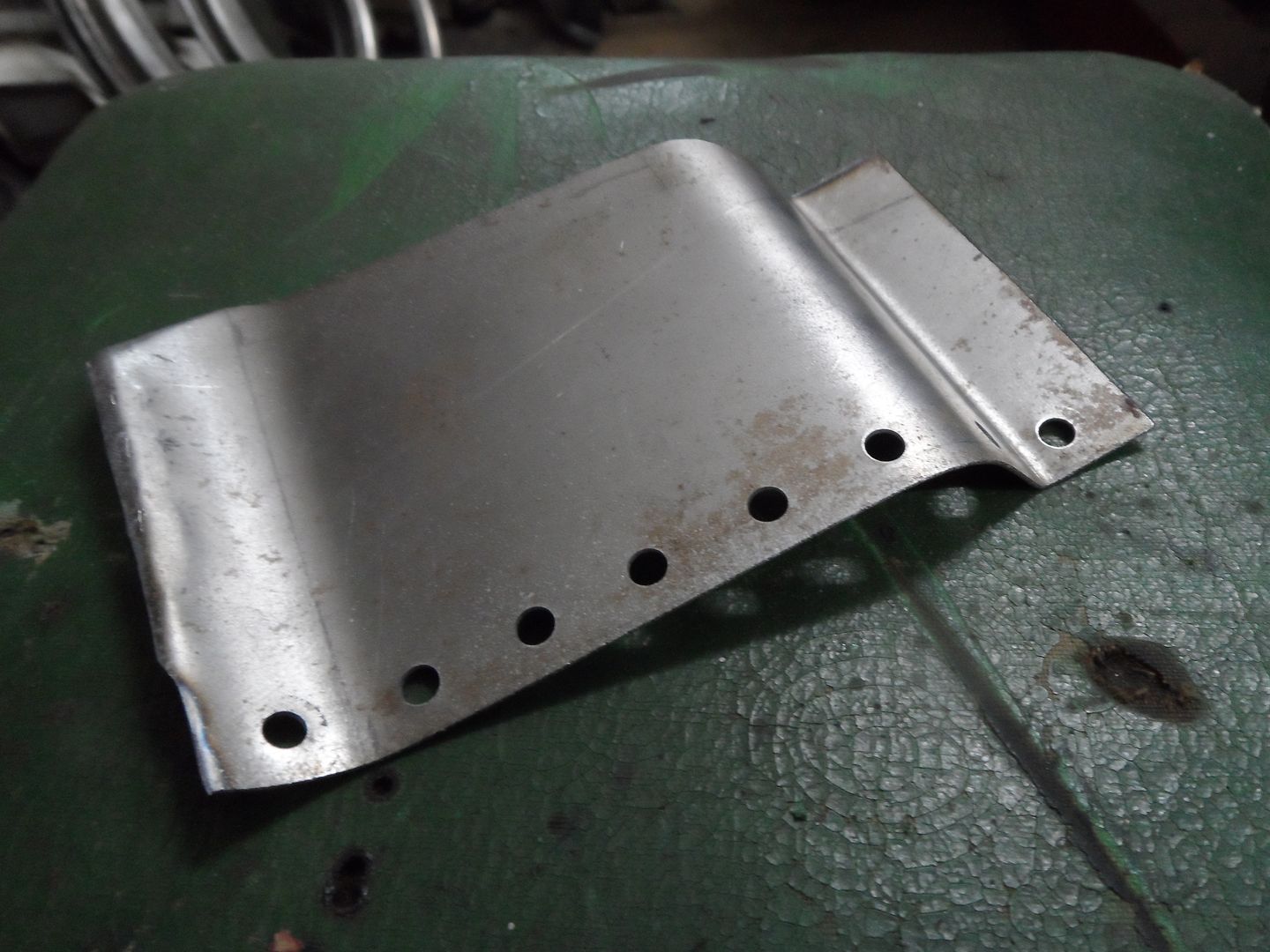

Cut and bent an infill to connect the inner sill to the A pillar bar:

3mm spreader plates cut and welded into place:

Next I moved onto the wheel arches and finishing off the engine bay. There was a bulge for the throttle pedal stop which on my other car gets very close to the tyre so it had to come out:

Removed and plated over

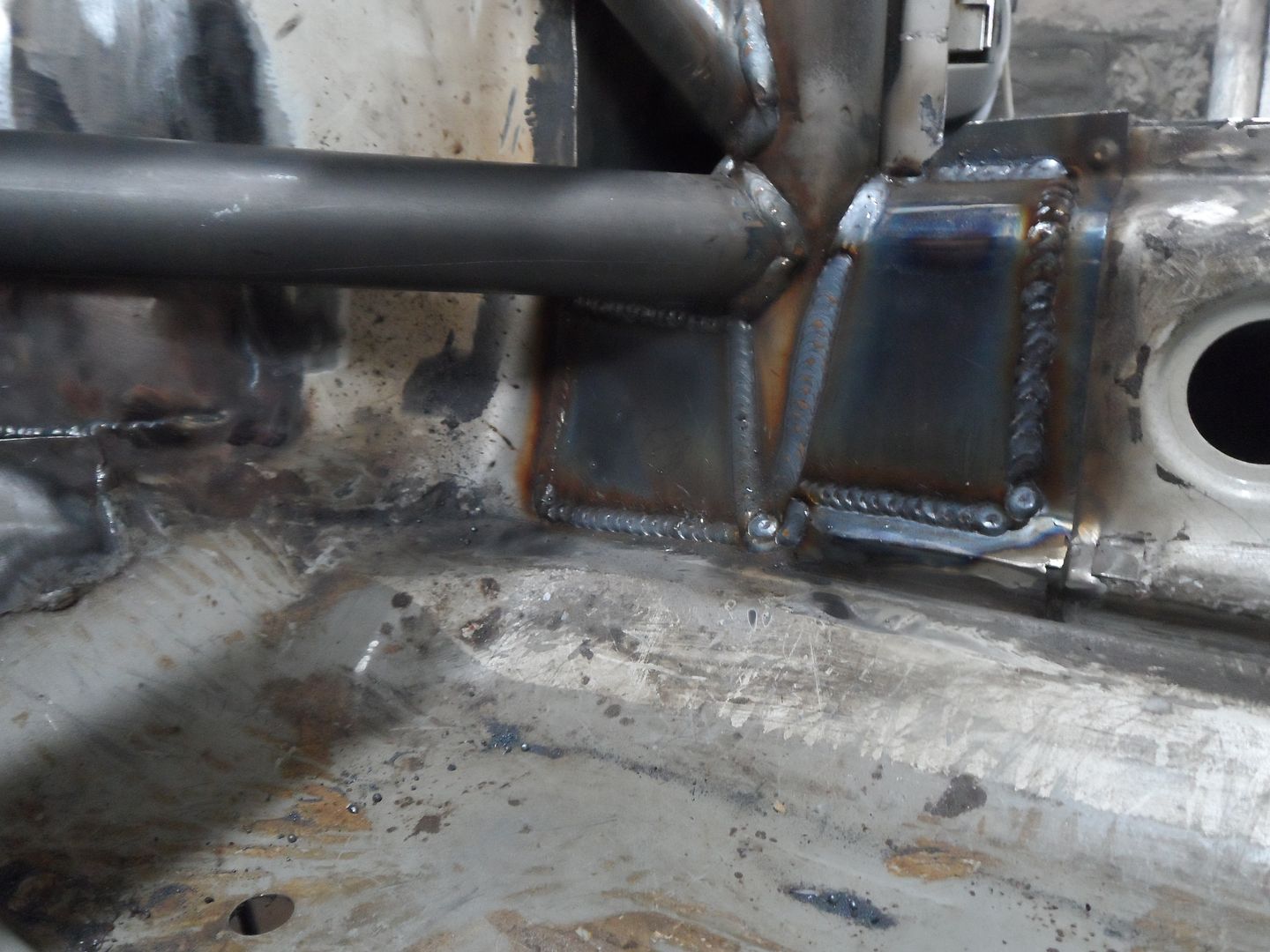

Many little repairs in the engine bay and the cage welded up then stripped back to bare metal and given a coat of paint to stop the rust

Cage tied into the inner arch to strengthen the steering rack mounting:

Finally I had a pair of kevlar inner arches made up. These will keep the weight nice and low and should stand up to the stones from the rear tyres

Lacquered on the inside. I will leave them bare kevlar I think so should look cool when the car is finished.

Back onto the inside of the car next to chase through the repairs and cage welding.

Comment

-

After I finished in the engine bay it was onto the inside of the car. First job was to weld the harness bosses into place. These go through the cage bar bolted in at the rear and welded at the front, no chance they can move!

Next was onto cutting out the rust in the floor and welding new metal in. It was largely solid so not that many issues to sort.

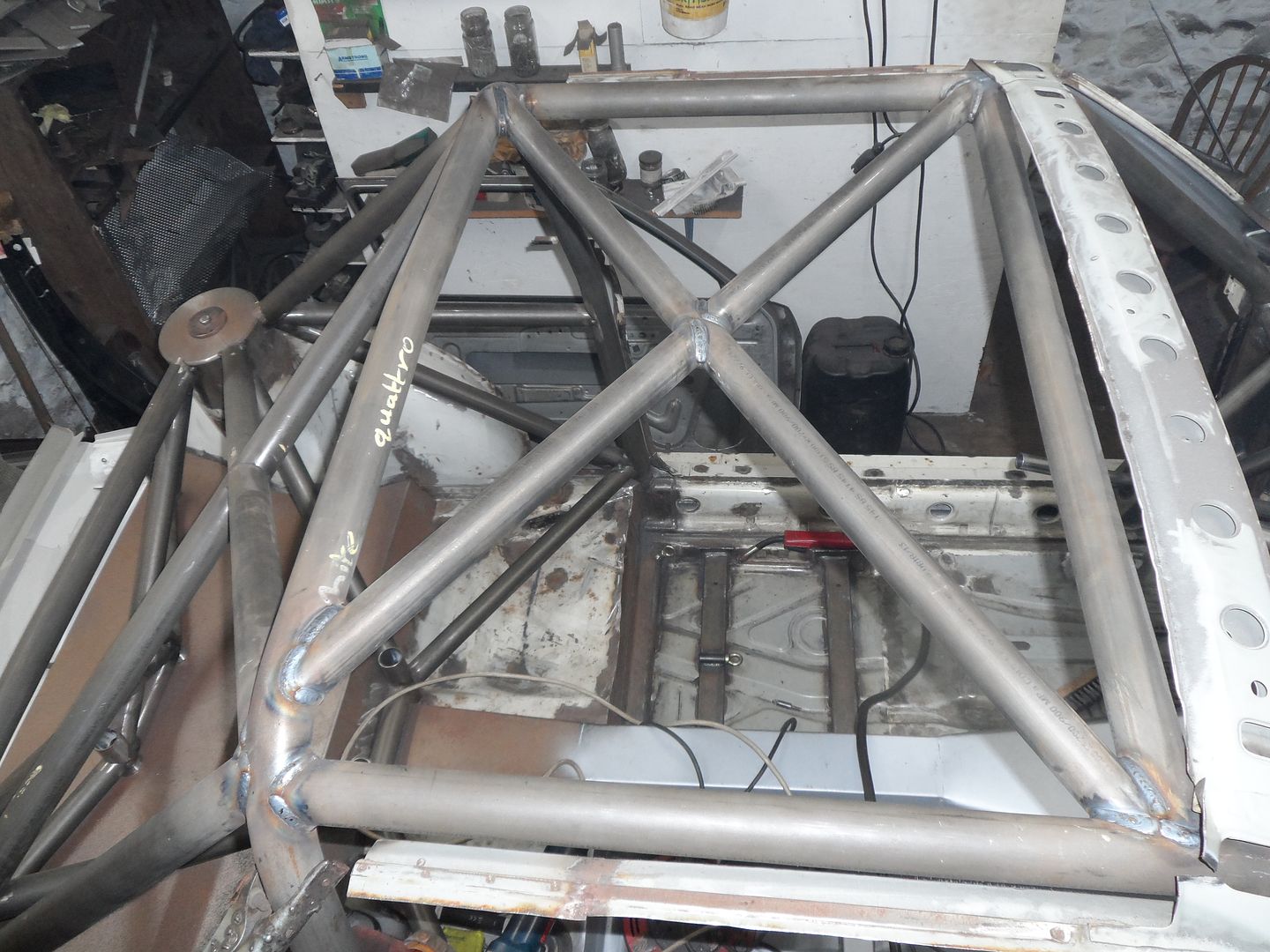

Next I welded the front section of cage

Welded the underside from lying on my back in the foot wells which was bloody awkward!

The final bit of welding to do on the floor was to get the tunnel finally welded up

That leaves the floor ready to strip down and prime

A couple of deliveries to keep me busy over Christmas. A lifeline snap off boss to start the steering

Finally a Tilton reverse pedal box which puts the master cylinders under your feet which allows it to be pushed tighter to the fire wall.

Hope to have the steering and pedals mounted in the next couple of weeks then its onto the rear floor and the final welding on the cage.

- 1 like

Comment

-

I don't build cars as a job no and I am not an engineer. I have learn't a lot from my dad as he is a very practical man and is into his vintage cars. The rest I have learn't along the way. Nothing like getting stuck in making a few mistakes and then solving them.

Sadly some people take a lot of stick for that in the days of the internet as they get jumped on for poor work.

Comment

-

Have been continuing the work on the car over the past few months. Now have all the floor cleaned back, welded and repaired where required. All the roll cage is welded and finally got the steering and pedals mounted.

Finally around to fitting the panels up now which is going to be a lot of work but its slowly progressing.

- 1 like

Comment

-

Lovely steelwork I bet you are ready for a change now mate, i'm looking forward to seeing some panels on it

I bet you are ready for a change now mate, i'm looking forward to seeing some panels on it

Have you done that bit out of Days of Thunder where you go in the lock-up and stroke the frame and talk to it? Panthero Coupé quattro 20vt

Panthero Coupé quattro 20vt

Indigo ABY coupé

Imola B6 S4 Avant

- 1 like

Comment

Comment