Its all T45 grade tubing, as used on all WRC cars.

Announcement

Collapse

No announcement yet.

Audi quattro S1 E2

Collapse

X

-

Not worked on the shell a great deal over summer as the weather has been far too nice and shell fabrication is horrible in hot weather! Will get back onto it full tilt over the winter months as the other car will be off the road so cant take up any time!

I have managed to get a little done on it. The rear tunnel had to go in before the cage tubing could be welded into place. This is again raised as per the rear floor to allow everything to run higher in the shell. Looks far better with the tunnel in as it links the 2 halves together visually. Then I completed the rear pick ups with the outer bosses. These will have a cradle going to the bottom of the rear diff to stop it twisting and I will also mount the rear anti roll bar on them that's why they are pushed back from the inner pick ups.

Going to complete the welding on the rear end and work forwards to complete the front tunnel and then extend the cage up to the front turrets and subframe pick ups. Should have more regular updates from now on!

Comment

-

Back on this project now as the other car is off the road for the winter. Started moving forwards through the shell as the rear end is more or less complete now from a roll cage point of view.

First job was to cap off the holes in the sills where the main hoop drops down through the floor.

This was the gap to fill:

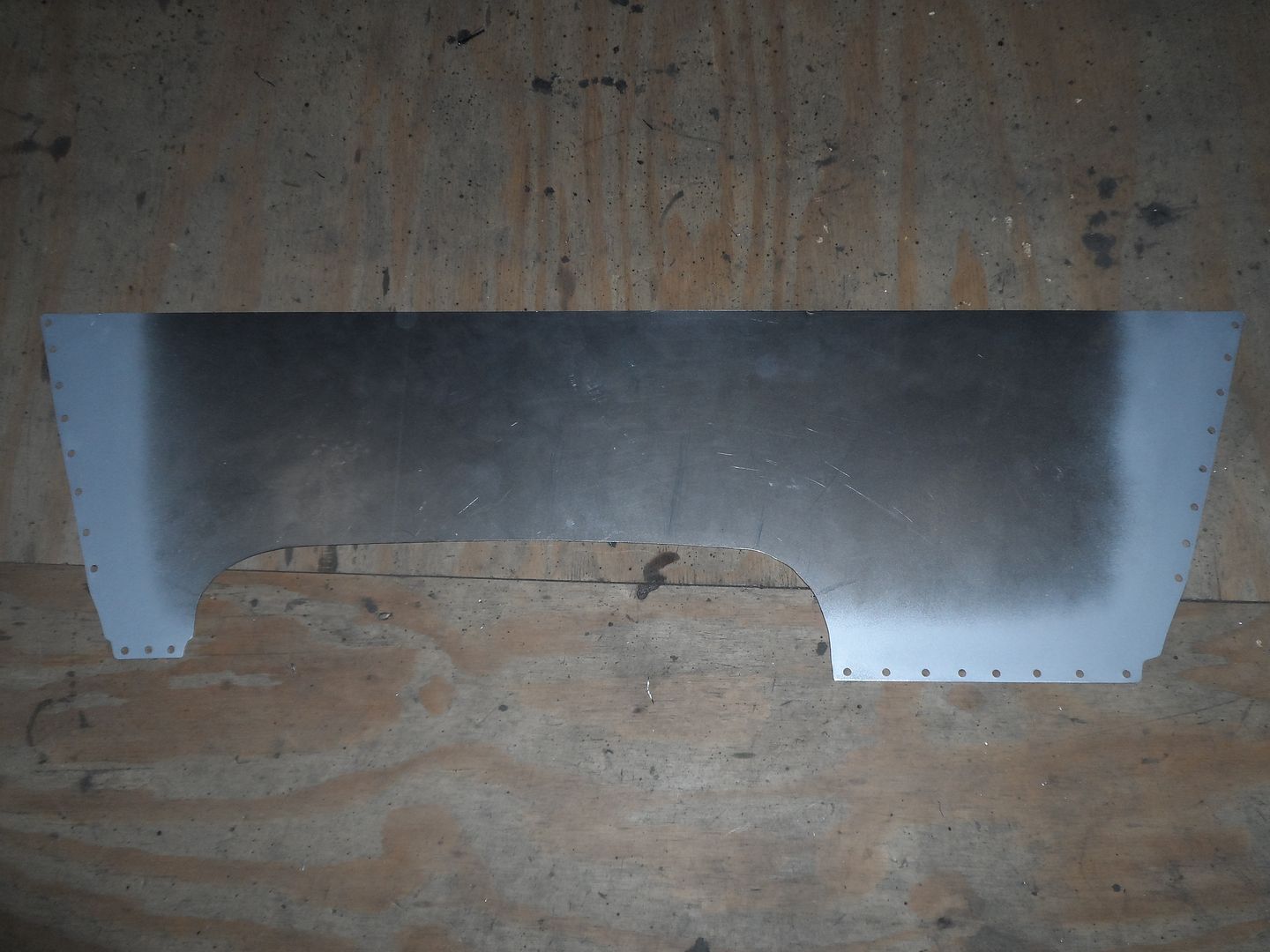

Cut and shaped some infill pieces:

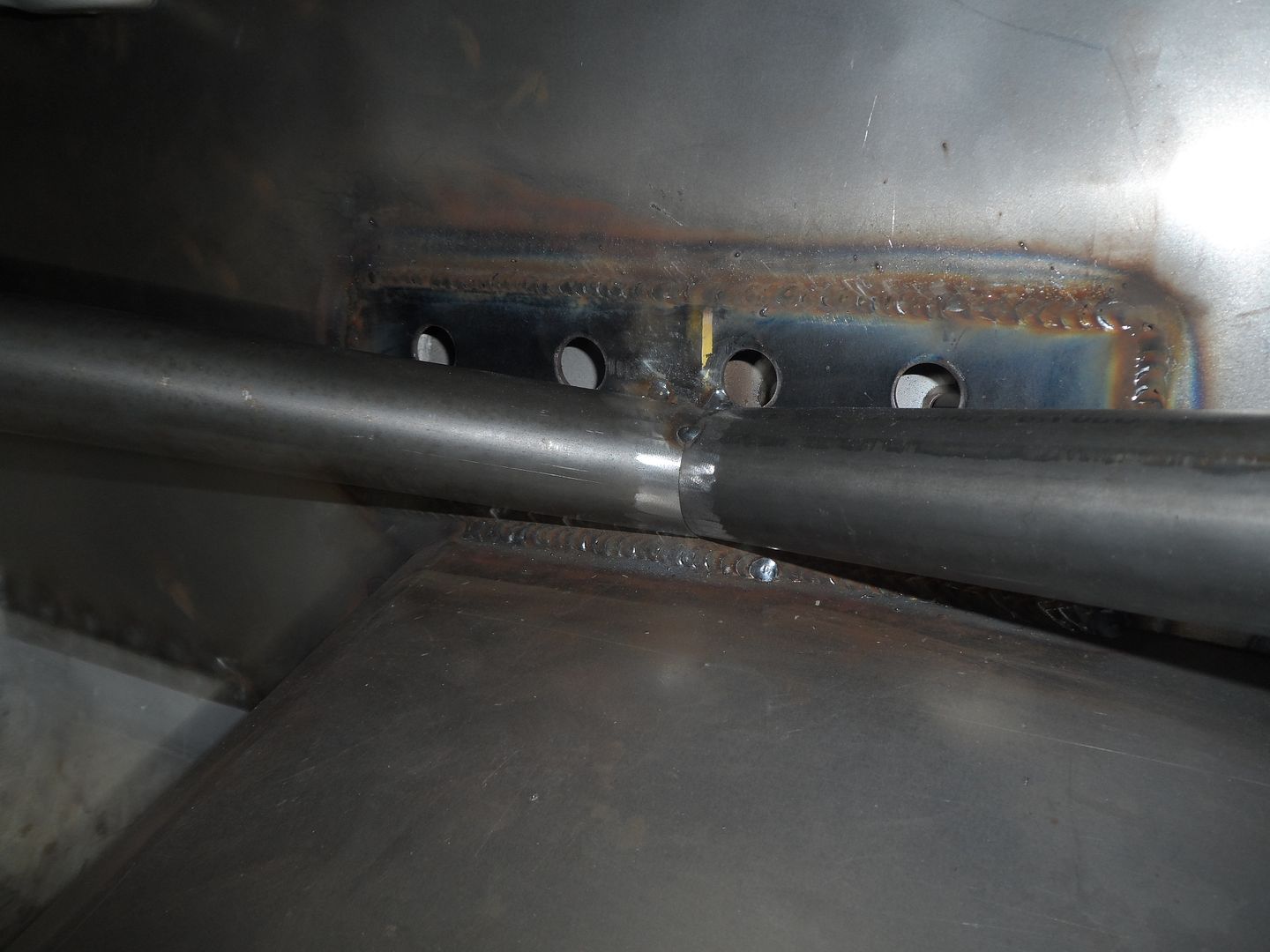

This was welded into the sill and a 3mm spreader plate added to the other side.

3mm spreader plate on top of the in fill piece to get the required 120 cm2 of plate.

Welded into position:

Repeated on the opposite side, now doesn't look like 2 halves of the car:

The next job I moved onto was to jig up the steering rack position so the larger tunnel could go in and also to raise the steering mount:

Sits on the centre of the cross bar for the top mount pick ups.

Jigged up all 4 holes on the bulkhead as 2 are for RHD and 2 for LHD.

So with that point tied into the jig the tunnel and mount were cut out. The tunnel is higher than standard to take into account the raised engine and drivetrain. Its also widened out at the mouth on the right hand side right up to the chassis rail so it can give the exhaust a much easier path.

Tunnel folded up to suit:

Tried a seat in, all looks good!

Next job was to remove the firewall as it wasn't worth welding all the holes and sorting it for left hand drive.

New firewall cut to fit and sprayed with weld through primer to protect the closed edges.

And welded into place:

Rain tray was chopped out as it was just excess weight.

Final job was to make a new steering bracket. Decided to make a new one rather than adapt the original to fit. Started off with some curved tube bolted up to the jig and then built it back to the firewall.

All welded up on the jig:

Quick coat of paint before it was sealed up with a backing plate which would sit through the firewall.

Welded into place raised up 50mm then the jig removed:

Bars added down from the A pillars to tie the bracket into the cage and to stop anything from coming back through the bulkhead:

That brings it up to date so far. I am moving onto the front section of the cage next which starts with some more billet top mounts to raise them up same as the rear ones. Then the cage will be tied down into the front subframe points. Its finally starting to look a little more complete now it doesn't have so many large holes in the floor pan or bulkhead!

Comment

-

Awesome work.... I'm drolling!

Can be road legal this home made cage?

Can be brought an already made cage , legal and ready to be bolted or welded on our Audis?RED Mitsubishi Lancer Evolution VI TME nº 16 of 250

BLACK Mitsubishi Lancer Evolution VI TME nº 189 of 250

LWB Audi Sport Quattro project

Comment

-

Love these updates Hamish The ONLY S2 Golf!

The ONLY S2 Golf!

http://www.s2forum.com/forum/showthread.php?t=19402

10.42@138mph

https://m.youtube.com/watch?v=0wnkkOfFpXg

Comment

-

I spend varying amounts of time on the shell. I barely touched it over summer, but lately I have put quite a few full days in.

The car will be road legal yes. You can buy a cage from custom cages, but the cage I have made is fully legal to MSA and FIA standards.

As for top mounts I am using these some that are designed for a mk2 escort with a big 20mm aurora bearing in them. They will be bolted on top of the turrets like a modern wrc car for ease of adjustability.

Comment

-

I have been working away on the shell over the past few months. First job was to do the seat rails. I wanted them nice and low as I am tall so like to be well down inside the car. First job was to weld some spreader plates in, then I sliced through the high point on the floor to get them to touch so it could be stitched into it for more strength.

Rails are 50 x 25mm box and the bolts pick up right through the floor to make access easier as that's something that's bugged me on the other car.

Next I moved onto finishing the mounting of the steering rack. Obviously it was right hand drive to begin with so the inner arch on the left required modifying so the rack could be bolted through it and also 50mm higher as per the centre mount.

Also extended the steering arm hole 50mm higher at the same time.

The opposite side had the RHD steering mounting and it had all sorts of bulges which I didn't like so that got chopped out and a new piece let in.

Finally I moved onto the top mounts. Same as the rear lathed some up out of billet.

Couldn't get them as high as I had wanted as the bonnet limits them even with the bulge on the S1 E2 bonnet. They are offset rearwards by 25mm to give more caster angle.

Couldn't go back any further with them.

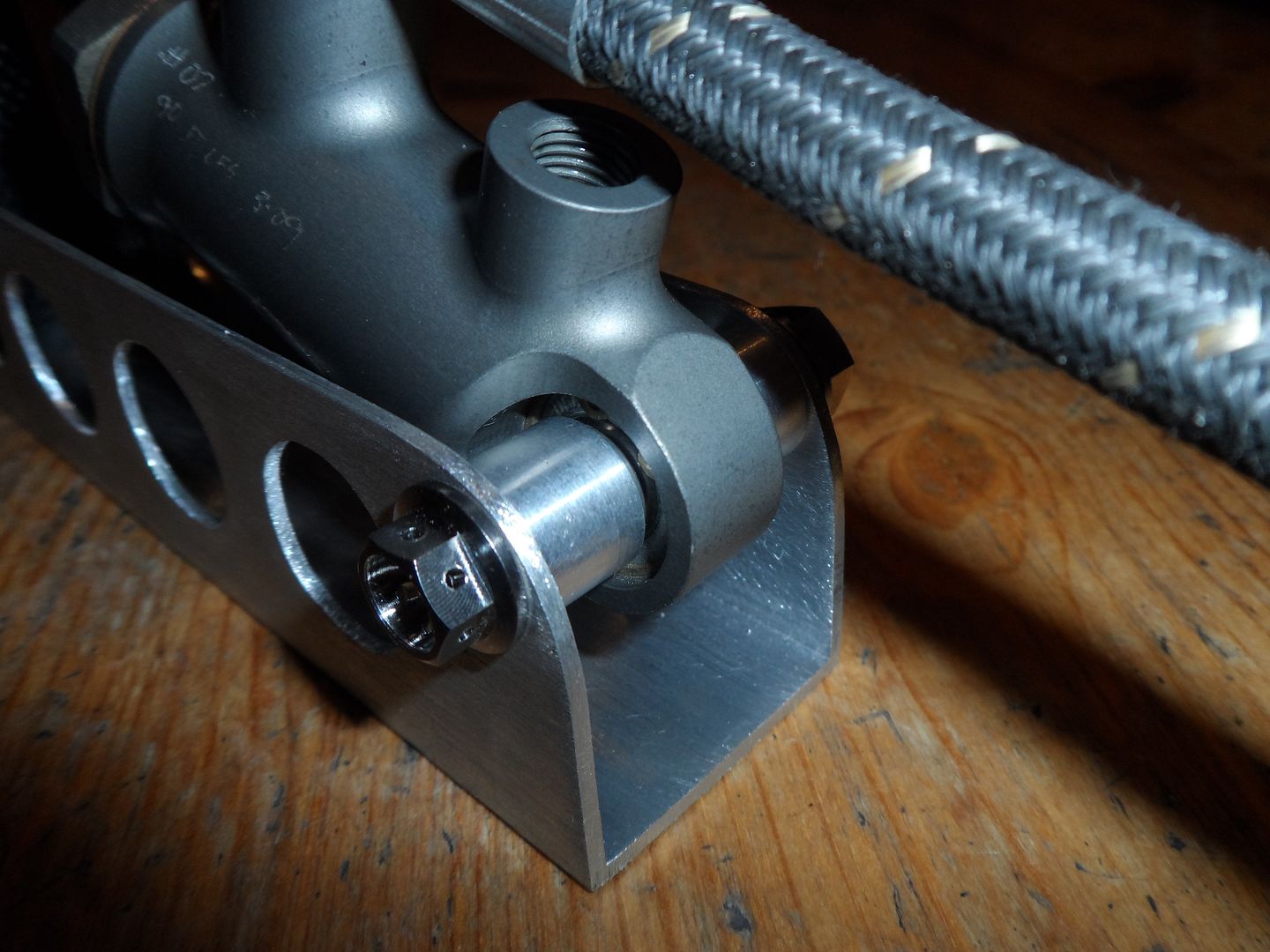

I had mentioned to a good mate of mine I was buying an AP racing handbrake as I was starting to mount up all the driver controls. He convinced me that I should make one, said it would be much nicer and a lot cheaper! Well its probably cost a lot more with my labour but it has turned out rather well if I do say so!

Uses a 25mm carbon shaft with an alloy insert in the base to help with the loading. Its bored up the centre so its super light.

Shaft uses a bike grip and an alloy plug to finish it off.

All bolted together with titanium bolts, nuts and washers. Shaft pivots on roller thrust bearings.

Now the top mounts are in I am going to get them tied into the cage and then from there drop down and pick up the front subframe points. Hopefully get a bit done over the festive period!

Comment

-

Cool stuff

What made you decide to make it left hand drive?

Comment

Comment